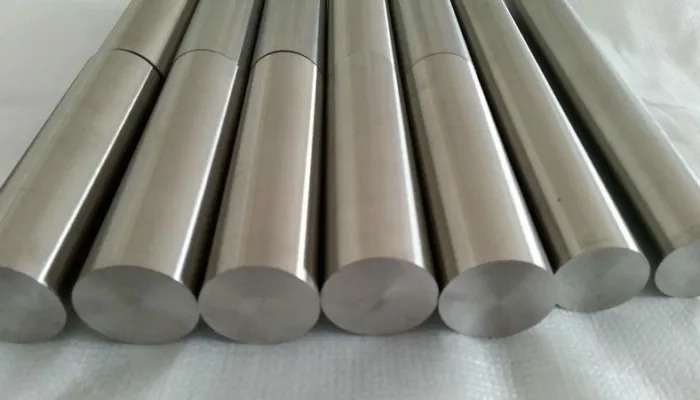

EN19 and EN24 are two of the most powerful and widely used alloy steels in modern engineering.

Both steels deliver exceptional mechanical performance, making them ideal for:

• Automotive components

• Oil & gas machinery

• Heavy-duty equipment

• Aerospace parts

• High-load shafts & gears

• Power transmission components

But the big question remains:

Which steel is better — EN19 or EN24?

Both offer excellent strength, heat treatment response, and wear properties,

but each grade has specific advantages.

In this detailed 2025 comparison guide, we break down the differences in:

• Mechanical properties

• Heat treatment performance

• Wear resistance

• Impact toughness

• Machinability

• Best industry applications

• Cost & long-term reliability

By the end of this article, you will know exactly which material is right for your project.

Welcome to Moksh Tubes & Fittings LLP

Monday - Friday : 8:00 AM to 7:00 PM

-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

EN19 vs EN24 — Which High-Strength Engineering Steel Performs Better in 2025? (Complete Technical Comparison Guide)

EN19 vs EN24 — Which High-Strength Engineering Steel Performs Better in 2025? (Complete Technical Comparison Guide)

Chemical Composition — The Root of Their Strength

Mechanical Properties Comparison

| Property | EN19 | EN24 |

|---|---|---|

| Tensile Strength | 850–1000 MPa | 1000–1400 MPa |

| Yield Strength | 600–800 MPa | 800–1000 MPa |

| Hardness (HRC) | 28–32 | 32–48 |

| Fatigue Strength | High | Very High |

| Impact Toughness | High | Extremely High |

Summary:

EN19 → Strong, balanced, economical

EN24 → Stronger, more shock resistant, premium grade

If your application faces impact loads, EN24 wins clearly.

Heat Treatment Capabilities — EN24 Dominates

EN19 and EN24 both respond excellently to heat treatment. But EN24 provides superior hardness & toughness due to its Nickel content.

EN19 Heat Treatment

- Great hardenability

- Excellent for gears, shafts

- Moderate through-hardening

EN24 Heat Treatment

- Deep hardening

- Very high impact strength

- Exceptional stability after tempering

- Best for dynamic loads

Winner for heat treatment: EN24

Wear Resistance — EN24 Performs Better

Wear resistance is critical for gears, shafts, and high-friction parts.

EN19 → Good wear resistance

EN24 → Outstanding wear resistance (even under extreme load)

⭐ Winner: EN24

Impact & Shock Resistance

This is the biggest performance difference.

⭐ EN19

Strong, reliable, handles moderate impact.

EN24 Built for extreme impact applications such as:

- Aircraft components

- Racing vehicles

- Mining equipment

- High-load rotating machines

EN24’s Nickel content makes it highly resistant to brittle failure under sudden shock.

⭐ Winner: EN24 by a large margin

Machinability — EN19 Is Better

EN24 becomes harder & tougher after heat treatment, making machining more difficult.

| Grade | Machinability |

|---|---|

| EN19 | ⭐⭐⭐⭐ (Good) |

| EN24 | ⭐⭐⭐ (Average / Difficult after hardening) |

If machining cost & time matter, EN19 is the better choice.

Corrosion Resistance

Both EN19 and EN24 are not corrosion-resistant steels unless coated.

However, EN24 has slightly better atmospheric resistance due to Nickel.

For corrosion-critical applications → choose Stainless Steel or Duplex.

Applications — Where Each Grade Is Best Used

Where EN19 Is Used (4140)

EN19 offers the best balance of strength + affordability.

- Automotive crankshafts

- Gear shafts & pinions

- Propeller shafts

- High-load bolts & studs

- Drill collars

- Connecting rods

- General engineering components

Where EN24 Is Used (4340)

- Aircraft landing gear

- Missile & defense components

- Helicopter rotor shafts

- Racing vehicle drivetrain parts

- Mining machinery

- Heavy industrial shafts

- Performance gears

If failure is not an option → EN24 is the choice.

Cost & Availability Comparison

| Grade | Cost | Availability | When to Choose |

|---|---|---|---|

| EN19 | Medium | Widely available | Balanced performance |

| EN24 | Higher | Available but premium | Extreme strength demands |

EN24 gives superior performance, but EN19 provides the best value for the price.

Which Should You Choose? (Simple Selection Guide)

Choose EN19 if:

- You need strong, reliable, cost-effective steel

- Machinability is important

- Application involves moderate to heavy load

- Budget matters

Choose EN24 if:

- You need maximum strength

- Application involves shock, impact, or high torque

- You want long-term durability under extreme stress

- You are designing for aerospace, racing, mining, or defense

Conclusion

EN19 and EN24 are both outstanding engineering steels, but serve different performance levels:

EN19 → the best all-rounder — strong, affordable, machinable, and reliable.

EN24 → the premium high-performance steel — unmatched strength, toughness, and wear resistance.

Industries choose EN19 for economical high strength, and EN24 for extreme mechanical demands where failure cannot be tolerated.

For both EN19 and EN24,

Moksh Tubes & Fittings LLP offers precision-engineered bars, rods, forgings, and machined components compliant with global standards.

FAQ's

Which steel is stronger: EN19 or EN24?

EN24 is significantly stronger due to its nickel-chromium-molybdenum composition.

Is EN24 harder than EN19?

Yes — EN24 achieves higher hardness after heat treatment.

Which is easier to machine?

EN19 is easier and more cost-effective to machine.

Is EN24 worth the extra cost?

Yes, if your application demands high strength, shock resistance, and durability.

Can EN19 and EN24 replace each other?

Sometimes yes — but EN24 should be chosen for critical, high-impact applications.

Recent Blogs

-

Hastelloy C276 vs Inconel 625 | Best Alloy for Chemical Plants

February 03, 2026

Locate Us

info@mokstubes.com

Office Address: Hinglaj Bhavan, Gulalwadi Mumbai, Maharashtra. 400004

Office Address: 6/A, Ground Floor, Rajwanti Mansion, Khetwadi Mumbai

Office Address: 95/95A, Dawood Baug, Sukhlaji Street, Kamatipura Mumbai

Office Address: 92E, Plot No. 3, New Tank Bunder, Darukhana, Mumbai, Maharashtra- 400 010.

get in touch

Let’s forge a connection — contact our team today.

Contact Us

At Moksh Tubes & Fittings LLP, we’re dedicated to making your purchases seamless — offering expert advice, a wide inventory of certified products, and global support for every order, large or small.

Get in TouchGet in Touch

We use cookies to personalize content, improve site performance, and analyze traffic. Some cookies are essential for the site to function correctly. You can manage your preferences or accept all cookies.