Choosing high quality stainless steel pipes welding remains one of the most important processes in industries such as chemical processing, pharmaceutical manufacturing, food-grade piping, power plants, HVAC systems, and high-pressure industrial lines. While stainless steel is known for durability and corrosion resistance, welding it requires far more skill and heat control than carbon steel.

Welcome to Moksh Tubes & Fittings LLP

Monday - Friday : 8:00 AM to 7:00 PM

-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Stainless Steel Pipe Welding: Complete Guide, Methods & Best Practices (2025 Edition)

Stainless Steel Pipe Welding: Complete Guide, Methods & Best Practices (2025 Edition)

Even small mistakes during installation can lead to leaks, corrosion at weld zones, and even system failure. This guide provides a clear, step-by-step process for installing stainless steel pipes properly. From preparation to joining methods and inspection, this ensures your project delivers long-lasting results.

Why Welding Stainless Steel Is Different

Stainless steel behaves differently due to chromium content and thermal characteristics. These demand strict control during welding:

- Higher Heat Sensitivity: Too much heat destroys the chromium layer → lower corrosion resistance.

- Sugaring (Internal Oxidation): Happens when inside of pipe isn’t purged, resulting in a weak, burnt weld root.

- Higher Expansion Rate: Causes distortion and misalignment if heat input isn't controlled.

Because of this, stainless steel requires strict management of:

- Cleanliness

- Shielding gas

- Heat input

- Purging

Essential Tools & Equipment for Stainless Steel Pipe Welding

- TIG welding machine (preferred)

- MIG welder (optional)

- SMAW/Stick welder (outdoor)

- Argon purging kit / purge dams

- Stainless steel filler rods

- Stainless steel wire brush

- Grinder with SS wheel

- Alignment clamps

- Temperature gun

- Acetone + lint-free cloths

Never use carbon steel brushes—they contaminate the weld and cause rust.

Preparing Stainless Steel Pipes Before Welding

Proper preparation determines 70% of weld quality. Follow these steps:

Edge Preparation

- Bevel angle: 35°

- Root gap: 1.5–2.5 mm

Cleaning

- Use only stainless steel cleaning tools

- Remove:

- Oil

- Grease

- Dirt

- Heat tint

- Oxides

- Wipe using acetone and clean cloth

Fit-Up

- Use clamps

- Apply tack welds

- Use spacers

- Correct fit-up prevents distortion and reduces rework

Welding Methods for Stainless Steel Pipes

TIG is the industry favorite, but other methods are also used depending on conditions.

A. TIG Welding (GTAW) – The Best Choice

TIG welding offers:

- Cleanest & strongest welds

- No spatter

- Full heat control

- Ideal for sanitary & high-purity applications

How to TIG Weld Stainless Steel Pipes

- Purge the inside of the pipe

- Maintain a short arc

- Use 100% argon gas

- Begin with root pass

- Use correct filler rod (308L / 316L)

- Avoid overheating

- Clean between passes

TIG welding produces the most corrosion-resistant weld root.

B. MIG Welding (GMAW)

Best Suited For

- Fast fabrication

- General shop production

- Non-sanitary applications

Pros & Cons

| Pros | Cons |

|---|---|

| Fast | Higher heat input |

| Easy to learn | More spatter |

| Good for workshops | Not ideal for food/pharma use |

C. Stick Welding (SMAW)

Perfect For

- Outdoor welding

- Thick-wall pipes

- Repair work

Recommended Electrodes

- E308L-16

- E316L-16

Purging: The Most Important Step in Stainless Steel Pipe Welding

Purging removes oxygen inside the pipe and prevents weld oxidation.

Best Purging Practices

- Use 100% Argon

- Seal both ends of the pipe

- Use purge dams or tape

- Keep oxygen below 0.1% (1000 PPM)

A correct weld root should be:

- Smooth

- Silver

- Free from contamination

Without purging → sugaring → failure in pressure systems.

Selecting the Right Filler Metal

Incorrect filler selection can weaken the weld and reduce corrosion resistance.

Recommended Filler Rods

| Base Material | Filler Rod |

|---|---|

| 304 / 304L | ER308L |

| 316 / 316L | ER316L |

| Duplex | ER2209 |

| Super Duplex | ER2594 |

Use L-grade filler for maximum corrosion resistance.

Common Weld Defects & Prevention Tips

| Defect | Cause | Prevention |

|---|---|---|

| Sugaring | Poor purging | Maintain argon flow & seal pipe |

| Cracking | Excess heat | Lower amperage & interpass temp |

| Porosity | Dirty or moist rods | Keep filler dry |

| Distortion | High heat input | Clamp pipe & use smaller beads |

| Undercut | Wrong torch angle | Use steady travel speed |

Professional Welding Sequence for Stainless Steel Pipes

Welding Sequence

- Fit-up & tack weld

- Purging setup

- Root pass

- Hot pass

- Filler pass

- Final cap pass

- Clean between each pass

- Final inspection

This ensures:

- Leak-proof welds

- Strong mechanical integrity

- Smooth internal weld bead

Post-Weld Cleaning & Passivation

Mechanical Cleaning

- SS wire brush

- SS grinding wheel

- Flap disc

Pickling & Passivation Removes:

- Heat tint

- Surface contamination

- Micro impurities

Restores chromium oxide layer → maximum corrosion resistance.

Weld Inspection Standards (ASME Approved)

Commonly used inspection methods include:

- Visual Testing (VT)

- Dye Penetrant Testing (DPT)

- Radiographic Testing (RT)

- Ultrasonic Testing (UT)

- Hydrostatic Pressure Test

These are mandatory for pressure pipelines and critical components.

Applications of Stainless Steel Pipe Welding

- Oil & gas refineries

- Chemical processing

- Heat exchangers

- Food & beverage plants

- Pharmaceutical systems

- Marine pipelines

- Water treatment

- Fire-fighting systems

- HVAC lines

Why Choose Moksh Tubes & Fittings LLP?

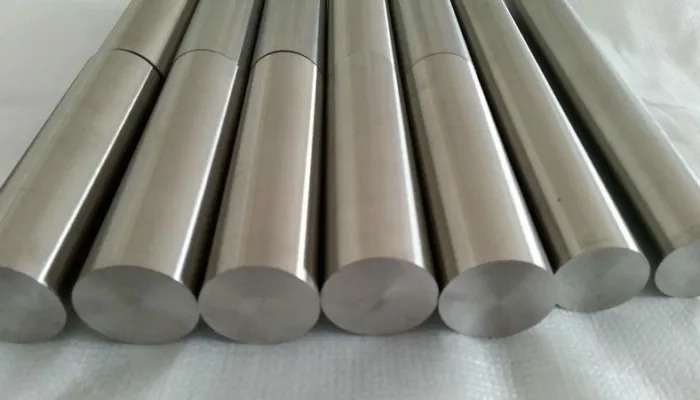

- High-quality stainless steel pipes (304, 316, 316L)

- Seamless & welded tubes

- Flanges & fittings

- Precision manufacturing

- Global shipping

For reliable, corrosion-resistant stainless steel pipes, Moksh Tubes delivers unmatched performance.

FAQ's

What is the best welding method for stainless steel pipes?

TIG welding provides the strongest and cleanest welds with excellent heat control.

Is purging required for stainless steel pipe welding?

Yes, purging prevents oxidation inside the pipe and ensures a strong weld root.

What filler rod is best for welding SS 316?

ER316L is recommended for welding 316/316L stainless steel.

How do I prevent distortion in stainless steel welding?

Use low heat, proper clamping, and smaller beads to minimize distortion.

Can stainless steel be welded outdoors?

SMAW (Stick welding) is suitable for outdoor work since wind affects shielding gas.

Recent Blogs

-

Hastelloy C276 vs Inconel 625 | Best Alloy for Chemical Plants

February 03, 2026

Locate Us

info@mokstubes.com

Office Address: Hinglaj Bhavan, Gulalwadi Mumbai, Maharashtra. 400004

Office Address: 6/A, Ground Floor, Rajwanti Mansion, Khetwadi Mumbai

Office Address: 95/95A, Dawood Baug, Sukhlaji Street, Kamatipura Mumbai

Office Address: 92E, Plot No. 3, New Tank Bunder, Darukhana, Mumbai, Maharashtra- 400 010.

get in touch

Let’s forge a connection — contact our team today.

Contact Us

At Moksh Tubes & Fittings LLP, we’re dedicated to making your purchases seamless — offering expert advice, a wide inventory of certified products, and global support for every order, large or small.

Get in TouchGet in Touch

We use cookies to personalize content, improve site performance, and analyze traffic. Some cookies are essential for the site to function correctly. You can manage your preferences or accept all cookies.