The industrial piping industry is on the brink of a significant transformation. With advancements in materials, sustainability goals, and automation technologies, the piping sector is evolving to meet the growing demands of global industries. Whether it's oil and gas, water treatment, manufacturing, or chemical plants, industrial piping trends are shaping the future to become more efficient, sustainable, and resilient.

Welcome to Moksh Tubes & Fittings LLP

Monday - Friday : 8:00 AM to 7:00 PM

-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Emerging Trends in Industrial Piping for 2025 and Beyond

Emerging Trends in Industrial Piping for 2025 and Beyond

From stainless steel innovations to automated monitoring systems, this article explores the key trends driving the global pipe industry for 2025 and beyond. These insights will help industry leaders stay ahead of the curve while making informed decisions for their operations.

The Growing Role of Sustainability in Piping

One of the most significant trends influencing the industrial piping sector is sustainability. With global initiatives pushing for reduced carbon emissions and higher energy efficiency, industries are focusing on environmentally friendly piping solutions.

Eco Friendly Materials

Traditional piping materials like carbon steel are being evaluated against newer, greener alternatives. Stainless steel piping innovations are leading steel piping innovations are leading the way due to their recyclable nature, low maintenance costs, and extended lifespan. Duplex and super duplex stainless steels are particularly attractive because of their superior strength, which allows for thinner walls and reduced material use.

Energy Efficient Systems

Energy-intensive piping systems are being optimized with heat exchangers, insulation innovations, and designs that minimize energy losses. This trend is especially visible in power generation and desalination plants, where new stainless steel grades, such as SMO 254, are being used to enhance system efficacy and durability.

What This Means for 2025 and Beyond

Sustainability-focused piping systems will likely dominate the global market as industries continue to prioritize environmental regulations and efficient operations. Stainless steel innovations, in particular, are expected to drive growth due to their role in meeting green infrastructure goals.

Smart Piping Systems and Automation

Automation is transforming how piping systems are operated and maintained. With advancements in the Internet of Things (IoT) and sensor technology, smart piping systems are becoming the new standard in industrial sectors.

Integrated Monitoring Systems

Smart piping solutions equipped with IoT sensors are enabling real-time monitoring of flow rate, temperature, and pressure. These systems can detect leaks or blockages before they escalate, minimizing downtime and reducing repair costs.

Example Innovation: Stainless steel pipes with integrated sensors are now being designed to detect and report corrosion levels, ensuring that maintenance is performed exactly when needed.

Predictive Maintenance

Instead of relying on traditional reactive maintenance, industries are moving towards predictive maintenance using machine learning algorithms. These systems analyze piping performance data to predict potential failures weeks or even months in advance, allowing for timely interventions.

Implications for the Future

The adoption of smart piping and automation will streamline operations, cut costs, and enhance safety across industries. By 2025, expect most new industrial piping installations to incorporate some level of IoT-enabled technology.

Innovations in Stainless Steel

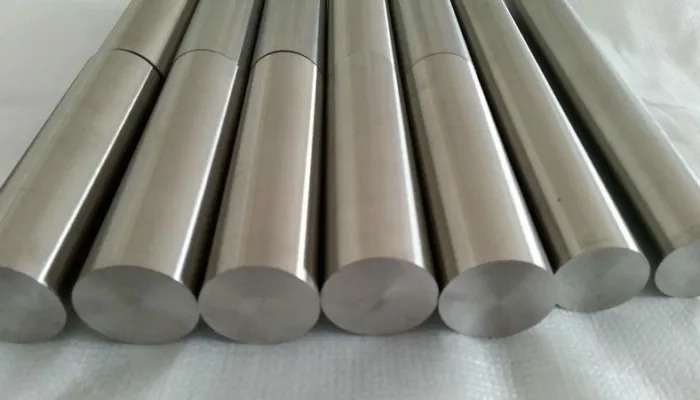

Stainless steel continues to be the material of choice for industrial piping due to its versatility, durability, and resistance to corrosion. Recent innovations are further enhancing its properties, making it indispensable in high-demand sectors.

Advanced Corrosion Resistance

Industrial applications like seawater desalination, chemical processing, and oil pipelines require materials that can withstand corrosive environments. New alloys, such as nitrogen-enriched stainless steels and nickel-molybdenum combinations, offer even greater resistance to pitting and crevice corrosion.

Example Spotlight: The introduction of duplex and super duplex stainless steels allows for the construction of lightweight yet robust piping systems that endure harsh environments while reducing lifecycle costs.

Improved Heat Resistance

Innovations in stainless steel are also addressing high-temperature applications. For instance, specialized grades, like 310 and 321 stainless steel, are being used in industries like power generation and aerospace where heat resistance is critical.

Industry Forecast

Stainless steel will remain at the forefront of industrial piping innovation in the coming years, with new grades and alloys pushing the boundaries of performance. By 2025, the incorporation of advanced stainless steel in piping systems is projected to grow by over 15% globally.

Modular and Prefabricated Piping Systems

Pre-fabrication and modular designs are becoming increasingly popular in the piping sector. These systems deliver unparalleled benefits in terms of installation speed, cost efficiency, and scalability.

Faster Installation and Reduced Costs

Modular piping systems are pre-engineered in controlled environments, allowing for quick on-site assembly. This reduces manual labor requirements and installation errors, leading to lower overall project costs.

Example Trend: Modular piping solutions made from stainless steel are being used in high-stakes environments like chemical plants, where precision and durability are key.

Scalability and Flexibility

Industries are looking for piping systems that can adapt to future upgrades or expansions. Prefabricated modular systems simplify scalability by allowing components to be added or modified without disrupting existing operations.

Global Market Growth and Regional Highlights

The global industrial piping market is poised for significant growth over the next few years, fueled by both innovation and infrastructure development.

Rising Demand in Emerging Economies

Countries in Asia, the Middle East, and Africa are driving demand for efficient, durable piping systems. Key applications include water treatment facilities, oil and gas pipelines, and renewable energy projects. Stainless steel piping, with its corrosion resistance and low-maintenance characteristics, is playing a significant role in meeting these demands.

Focus on Infrastructure Modernization

Developed nations are investing in modernizing aging piping systems to improve efficiency and comply with stricter environmental regulations. Stainless steel innovations, coupled with IoT-based monitoring systems, are central to these upgrades.

Final Thoughts

The industrial piping industry is entering a dynamic era where innovations in materials, technology, and design are transforming the global landscape. From eco friendly solutions to IoT enabled smart systems, the trends shaping 2025 and beyond will dictate how industries manage efficiency, sustainability, and operational resilience.

For companies looking to stay competitive, investing in advanced piping solutions like stainless steel innovations and modular systems is no longer optional it’s essential.

FAQ's

What are the key industrial piping trends for 2025 and beyond?

By 2025, industrial piping will be shaped by sustainability, IoT enabled smart systems, stainless steel innovations, and modular prefabricated designs. These advancements will improve efficiency, reduce environmental impact, and enhance operational resilience in industries like oil & gas, water treatment, and manufacturing.

Why is stainless steel becoming more important in industrial piping?

Stainless steel offers superior corrosion resistance, durability, recyclability, and heat resistance, making it ideal for demanding environments. New grades like duplex, super duplex, SMO 254, and heat-resistant alloys (310, 321) are expanding its applications in sectors like desalination, chemical processing, and power generation.

How are smart piping systems transforming industrial operations?

Smart piping systems use IoT sensors for real-time monitoring of temperature, pressure, and flow rates. They enable predictive maintenance, detect leaks early, and optimize performance—reducing downtime, cutting costs, and improving safety.

What are the benefits of modular and prefabricated piping systems?

Modular piping systems offer faster installation, reduced labor costs, and easier scalability for future expansions. Prefabrication ensures precision manufacturing, minimizes on-site errors, and is ideal for high-stakes environments like chemical plants.

Which regions are driving global industrial piping market growth?

Emerging economies in Asia, the Middle East, and Africa are fueling demand due to rapid infrastructure development, especially in water treatment, renewable energy, and oil & gas. Developed countries are focusing on upgrading aging systems with stainless steel and IoT enabled technologies.

Recent Blogs

-

Hastelloy C276 vs Inconel 625 | Best Alloy for Chemical Plants

February 03, 2026

Locate Us

info@mokstubes.com

Office Address: Hinglaj Bhavan, Gulalwadi Mumbai, Maharashtra. 400004

Office Address: 6/A, Ground Floor, Rajwanti Mansion, Khetwadi Mumbai

Office Address: 95/95A, Dawood Baug, Sukhlaji Street, Kamatipura Mumbai

Office Address: 92E, Plot No. 3, New Tank Bunder, Darukhana, Mumbai, Maharashtra- 400 010.

get in touch

Let’s forge a connection — contact our team today.

Contact Us

At Moksh Tubes & Fittings LLP, we’re dedicated to making your purchases seamless — offering expert advice, a wide inventory of certified products, and global support for every order, large or small.

Get in TouchGet in Touch

We use cookies to personalize content, improve site performance, and analyze traffic. Some cookies are essential for the site to function correctly. You can manage your preferences or accept all cookies.