-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

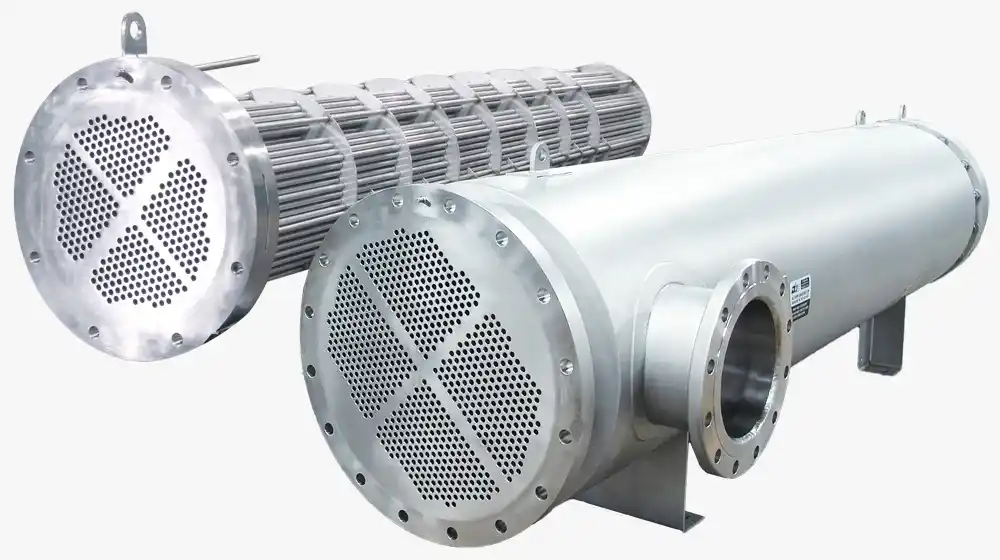

Boiler & Heat Exchanger Tubes are core components for thermal power plants, petrochemical units, refineries, and process industries. They are designed in such a way that they can safely handle high temperatures, pressure, and corrosive media, while also maintaining efficient heat transfer and stable performance.

manufactured from high grade stainless steel, carbon steel, alloy steel, and specialty alloys, which meet strict dimensional tolerances and international quality standards (ASTM, ASME, DIN, EN). This ensures their performance, safety, and reliability for industrial applications.

As a trusted supplier, exporter, and stockist, Moksh Tubes & Fittings LLP provides boiler and heat exchanger tubes. We source our materials from reputed mills that use advanced cold drawing, seamless forming, and welding technologies. This combination ensures precision, durability, and consistent performance for boilers, superheaters, condensers, heat exchangers, and other critical systems.

Download Boiler Heat Exchanger Tubes Datasheet

Get the complete Boiler Heat Exchanger Tubes datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Boiler & Heat Exchanger Tube Specifications

| Category | Details |

|---|---|

| Material | Stainless Steel, Duplex & Super Duplex Steel, Nickel Alloys, Inconel, Monel, Titanium, Copper Alloys, Alloy Steel, Carbon Steel |

| Grades | ASTM/ASME certified – available in all mentioned alloys |

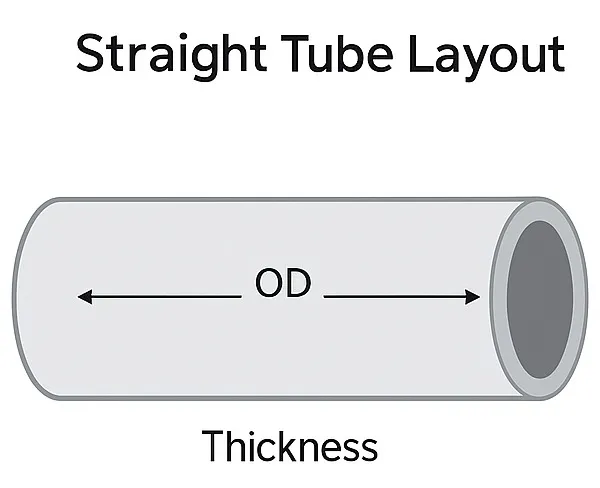

| Outer Diameter (OD) | 6 mm to 219 mm (¼” to 8” NB) |

| Wall Thickness | 0.5 mm to 12.7 mm (standard & custom schedules) |

| Lengths | Up to 12 meters or cut-to-length as per project needs |

| Finishes | Bright Annealed, Pickled & Passivated, Electro Polished, Matte |

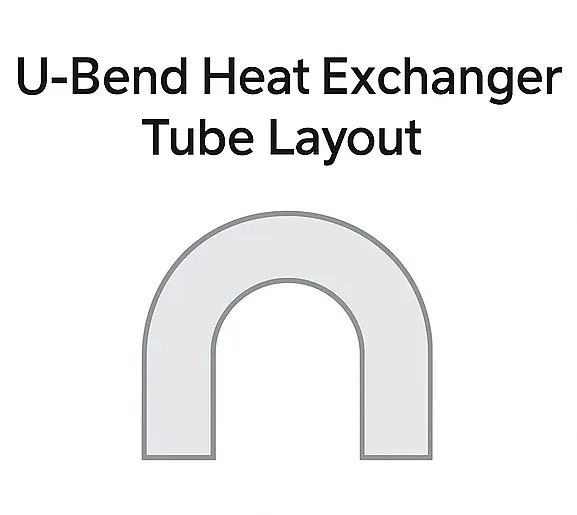

| Type | Seamless, Welded (ERW, EFW), U-Bent Tubes |

| Standards | ASTM A179, A192, A213, A249, A269, A333, ASME SA213, EN 10216, DIN standards |

| Applications | Boilers, Heat Exchangers, Superheaters, Condensers, Economizers |

Weight Chart (ASME B36.10 / B36.19)

Weight Chart (ASME B36.10 / B36.19 – Size & Weight Data)

| Nominal Bore Chart | Outside Diameter (O.D) (mm) |

Schedule 5C | Schedule 10C | Schedule 40C | Schedule 80C | Schedule 160C | Schedule XXC | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inches | Wt | Weight | Wt | Weight | Wt | Weight | Wt | Weight | Wt | Weight | Wt | Weight | |

| 3 | 1/8 | 10.3 | 0.2 | 0.01 | 0.3 | 0.02 | 0.4 | 0.03 | 0.6 | 0.04 | 0.8 | 0.06 | 1.0 | 0.07 |

| 6 | 1/4 | 13.7 | 0.2 | 0.02 | 0.3 | 0.03 | 0.4 | 0.04 | 0.6 | 0.06 | 0.8 | 0.08 | 1.0 | 0.10 |

| 10 | 3/8 | 17.1 | 0.2 | 0.03 | 0.3 | 0.04 | 0.4 | 0.06 | 0.6 | 0.08 | 0.8 | 0.11 | 1.0 | 0.14 |

| 15 | 1/2 | 21.3 | 0.2 | 0.04 | 0.3 | 0.06 | 0.4 | 0.08 | 0.6 | 0.12 | 0.8 | 0.16 | 1.0 | 0.20 |

| 20 | 3/4 | 26.7 | 0.2 | 0.06 | 0.3 | 0.09 | 0.4 | 0.12 | 0.6 | 0.17 | 0.8 | 0.22 | 1.0 | 0.28 |

| 25 | 1 | 33.4 | 0.2 | 0.08 | 0.3 | 0.12 | 0.4 | 0.17 | 0.6 | 0.25 | 0.8 | 0.33 | 1.0 | 0.41 |

| 32 | 1 1/4 | 42.2 | 0.2 | 0.13 | 0.3 | 0.19 | 0.4 | 0.26 | 0.6 | 0.38 | 0.8 | 0.50 | 1.0 | 0.62 |

| 40 | 1 1/2 | 48.3 | 0.2 | 0.16 | 0.3 | 0.24 | 0.4 | 0.32 | 0.6 | 0.48 | 0.8 | 0.63 | 1.0 | 0.78 |

| 50 | 2 | 60.3 | 0.2 | 0.24 | 0.3 | 0.36 | 0.4 | 0.47 | 0.6 | 0.70 | 0.8 | 0.93 | 1.0 | 1.17 |

| 65 | 2 1/2 | 73.0 | 0.2 | 0.33 | 0.3 | 0.49 | 0.4 | 0.65 | 0.6 | 0.97 | 0.8 | 1.29 | 1.0 | 1.63 |

| 80 | 3 | 88.9 | 0.2 | 0.47 | 0.3 | 0.70 | 0.4 | 0.93 | 0.6 | 1.40 | 0.8 | 1.87 | 1.0 | 2.36 |

| 100 | 4 | 114.3 | 0.2 | 0.77 | 0.3 | 1.14 | 0.4 | 1.52 | 0.6 | 2.27 | 0.8 | 3.04 | 1.0 | 3.82 |

| 125 | 5 | 141.3 | 0.2 | 1.17 | 0.3 | 1.72 | 0.4 | 2.30 | 0.6 | 3.42 | 0.8 | 4.58 | 1.0 | 5.76 |

| 150 | 6 | 168.3 | 0.2 | 1.63 | 0.3 | 2.41 | 0.4 | 3.23 | 0.6 | 4.79 | 0.8 | 6.38 | 1.0 | 8.02 |