Stainless steel is celebrated for its remarkable strength and resistance to corrosion. This reputation can sometimes lead to the misconception that it's completely immune to rust and requires no care. While stainless steel is incredibly durable, it is not entirely "stain proof." Under certain conditions, even this robust material can show signs of discoloration or corrosion. The key to ensuring its legendary longevity is a proper and consistent maintenance routine.

Welcome to Moksh Tubes & Fittings LLP

Monday - Friday : 8:00 AM to 7:00 PM

-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

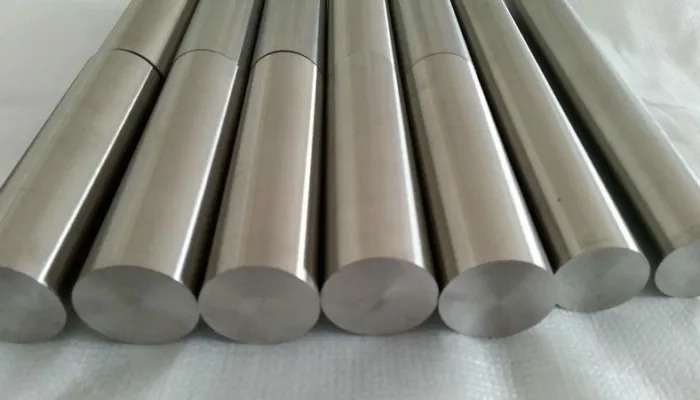

Maintenance Tips for Stainless Steel Tubes to Prevent Rust

Maintenance Tips for Stainless Steel Tubes to Prevent Rust

Proper care preserves the aesthetic appeal of your stainless steel tubes and protects their structural integrity, ensuring safety and performance for decades. A simple maintenance plan prevents costly repairs and premature replacements. This guide offers actionable tips for cleaning, inspecting, and protecting your stainless steel tubes, keeping them in prime condition and free from rust.

Understanding Why Stainless Steel Can Rust

The "stainless" quality of steel comes from a high chromium content, typically at least 10.5%. Chromium reacts with oxygen in the air to form a thin, invisible, and self healing passive layer of chromium oxide on the surface of the steel. This layer acts as a shield, protecting the iron in the alloy from rusting.

However, this protective layer can be compromised. The most common culprits are:

- Chloride Exposure: Salt from coastal air, de icing salts, or certain industrial chemicals can attack the passive layer, leading to pitting and crevice corrosion.

- Contamination with Iron Particles: If regular steel tools are used on stainless steel, they can leave behind small iron particles. These particles will rust, creating stains and potentially initiating corrosion on the stainless steel surface itself. This is known as "free iron" contamination.

- Harsh Chemicals: Abrasive cleaners or harsh chemicals like hydrochloric acid can strip away the passive layer, leaving the underlying steel vulnerable.

- Lack of Oxygen: In tight crevices where oxygen cannot circulate, the passive layer cannot reform if damaged, making these areas susceptible to corrosion.

The good news is that with the right maintenance practices, all these issues are preventable.

Essential Cleaning Techniques for Stainless Steel Pipes

Regular cleaning is the most effective way to prevent rust on stainless steel. It removes contaminants that could damage the passive layer and keeps the surface looking its best.

Routine Cleaning (Daily or Weekly)

For general upkeep, especially in architectural or less demanding environments, a simple cleaning routine is all you need.

- Use a mild detergent and warm water: A simple solution of soap or dish detergent in warm water is perfect for removing dirt, dust, and fingerprints.

- Apply with a soft cloth or sponge: Microfiber cloths are ideal as they won't scratch the surface.

- Wipe in the direction of the grain: Most stainless steel products have a visible brushed finish or "grain." Wiping along the grain helps avoid micro scratches and maintains the original look.

- Rinse thoroughly with clean water: This step is crucial. Rinsing removes any remaining soap residue, which could leave streaks or marks.

- Dry completely: Use a soft, dry cloth or a squeegee to wipe away all moisture. This prevents water spots and ensures the passive layer can reform properly in the presence of air.

Deep Cleaning for Stubborn Stains

For more difficult stains like oil, grease, or light discoloration, you may need a bit more effort.

- Use specialized stainless steel cleaners: Many commercial cleaners are formulated to remove tough stains without damaging the finish. Always follow the manufacturer's instructions.

- Try a paste of baking soda and water: For organic stains, a simple baking soda paste can be gently applied with a soft cloth. Let it sit for a few minutes before rinsing and drying.

- Vinegar for hard water spots: A solution of one part vinegar to three parts water can help dissolve mineral deposits from hard water. Remember to rinse thoroughly afterward as vinegar is acidic.

What to Avoid: The "Don'ts" of Stainless Steel Maintenance

What you don't do is just as important as what you do. Avoiding these common mistakes will save your stainless steel tubes from damage.

- DO NOT use steel wool or steel brushes: These will scratch the surface and, more importantly, leave behind iron particles that will rust and compromise the stainless steel. Always use non-metallic brushes or synthetic scouring pads.

- DO NOT use abrasive cleaners: Gritty or powdered cleaners can permanently scratch the finish of your stainless steel.

- DO NOT use cleaners containing chlorides: This includes many common household cleaners, especially those with bleach (sodium hypochlorite) or hydrochloric acid. Chlorides are the number one enemy of the passive layer.

- DO NOT clean in direct sunlight or on hot surfaces: The heat can cause cleaners to evaporate too quickly, leaving behind streaks and chemical residues.

Creating a Regular Maintenance Schedule

Consistency is key to effective stainless steel tube maintenance. The frequency of cleaning depends entirely on the application and environment.

- Architectural/Decorative (Indoors): Cleaning every 6-12 months is often sufficient to remove accumulated dust and grime. High touch areas like handrails may require more frequent wiping.

- Coastal or Marine Environments: The high concentration of airborne salt requires more frequent attention. A rinse with fresh water every 1-3 months can make a huge difference in preventing chloride buildup.

- Industrial/Chemical Plants: Maintenance schedules in these settings should be strict and tailored to the specific chemicals and conditions. Daily or weekly inspections and cleanings may be necessary to ensure safety and operational integrity.

- Food and Beverage Industry: Due to hygiene requirements, cleaning and sanitizing are typically performed daily or after each production run, using industry approved cleaning agents.

Inspection and Proactive Protection

Beyond cleaning, regular inspection can help you catch potential problems early.

- Check for Contamination: After installation or any mechanical work, inspect surfaces for any signs of "free iron" contamination (small rust spots). These can be removed with specialized solutions containing oxalic acid.

- Inspect Welds and Crevices: These areas are more susceptible to corrosion. Look for any signs of discoloration or pitting and address them immediately.

- Passivation: In some industrial applications, especially after welding or heavy fabrication, a process called passivation may be required. This involves treating the surface with a mild acid (like nitric or citric acid) to remove contaminants and help rebuild a robust passive layer.

A Small Investment for Long Term Performance

Maintaining your stainless steel tubes is not a difficult task, but it requires consistency and the right techniques. By following these simple maintenance tips, you can easily prevent rust, preserve the material's appearance, and ensure your investment continues to perform reliably for many years. A little proactive care goes a long way in upholding the strength and value of stainless steel.

Are you looking for high-quality stainless steel tubes that are built to last? Mokshtubes offers a wide selection of premium stainless steel products engineered for maximum durability and performance. Our expert team can also provide guidance on the best maintenance practices for your specific application. Explore our offerings or contact us today to find the perfect solution for your project.

Recent Blogs

-

Hastelloy C276 vs Inconel 625 | Best Alloy for Chemical Plants

February 03, 2026

Locate Us

info@mokstubes.com

Office Address: Hinglaj Bhavan, Gulalwadi Mumbai, Maharashtra. 400004

Office Address: 6/A, Ground Floor, Rajwanti Mansion, Khetwadi Mumbai

Office Address: 95/95A, Dawood Baug, Sukhlaji Street, Kamatipura Mumbai

Office Address: 92E, Plot No. 3, New Tank Bunder, Darukhana, Mumbai, Maharashtra- 400 010.

get in touch

Let’s forge a connection — contact our team today.

Contact Us

At Moksh Tubes & Fittings LLP, we’re dedicated to making your purchases seamless — offering expert advice, a wide inventory of certified products, and global support for every order, large or small.

Get in TouchGet in Touch

We use cookies to personalize content, improve site performance, and analyze traffic. Some cookies are essential for the site to function correctly. You can manage your preferences or accept all cookies.