-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

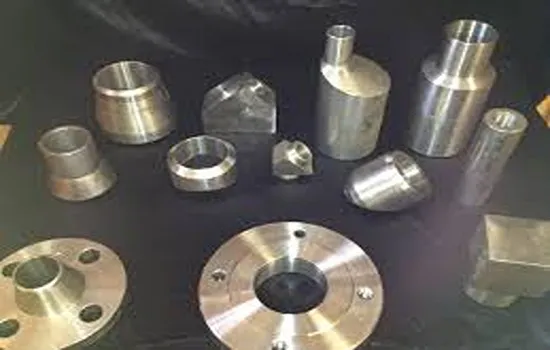

Custom Fabricated Fittings

Custom Fabricated Fittings are specialized piping and structural components supplied to meet unique design, dimensional, or operational requirements. Unlike standard fittings, these are engineered and fabricated to customer specifications ensuring perfect compatibility with project layouts, pressure ratings, and environmental conditions.

Moksh Tubes & Fittings LLP, we produce a wide range of custom fabricated fittings in materials like stainless steel, carbon steel, alloy steel, duplex & super duplex, titanium, and nickel alloys. Our fittings comply with ASTM, ASME, DIN, EN, and API standards, and are crafted using cutting, forming, bending, welding, and machining techniques to deliver precision and reliability for critical industries.

Specifications

| Category | Details |

|---|---|

| Material | Stainless Steel, Carbon Steel, Alloy Steel, Duplex & Super Duplex, Nickel Alloys, Titanium, Copper Alloys |

| Grades | ASTM, ASME, DIN, EN, and API certified grades – all major alloys available |

| Size Range | ½” NB to 72” NB (larger sizes on request) |

| Thickness | SCH 5 to SCH XXS (custom schedules available) |

| Types | Elbows, Tees, Reducers, Crosses, Stub Ends, Laterals, Headers, Manifolds, Y-pieces, Custom Shapes |

| Fabrication Methods | Cutting, Forming, Welding, Bending, Machining, CNC Finishing |

| Standards | ASTM A403, A815, B366, MSS-SP-43, ASME B16.9/B16.28 (as applicable) |

| Finishes | Pickled & Passivated, Bead Blasted, Mirror Polish (for decorative or sanitary applications) |

Product Range Charts

Weight Chart

| Fitting Type | Available Sizes (inches) | Wall Thickness (SCH) | Materials Available |

|---|---|---|---|

| Elbows (Short/Long Radius) | ½" – 48" | SCH 5 – SCH 160, XXS | Nickel Alloys, Stainless, Duplex, Titanium |

| Reducers (Concentric / Eccentric) | ½" – 48" | SCH 10 – SCH 160 | Hastelloy, Inconel, Monel, Alloy Steel |

| Tees / Crosses | ½" – 48" | SCH 10 – SCH 160 | SS, Duplex, Super Duplex, Copper Alloys |

| Stub Ends / Lap Joint | ½" – 24" | SCH 5 – SCH 80 | All Grades |

| Headers, Laterals, Branch Fittings | As per design | Custom wall thickness | On request |

Dimensions

Expanded Table (Long Radius Elbow – ASME B16.9)

| Nominal Pipe Size (NPS) | Outside Diameter (D) (mm) | Center-to-End (A) (mm) | Wall Thickness (t) (mm) |

|---|---|---|---|

| 2" | 60.3 | 76 | As per schedule |

| 4" | 114.3 | 152 | As per schedule |

| 8" | 219.1 | 305 | As per schedule |

| 12" | 323.9 | 457 | As per schedule |

| 24" | 610 | 914 | As per schedule |

Pressure Rating Chart

Expanded Table (Typical – for Welded Fabricated Fittings)

| Material | Class 150 | Class 300 | Class 600 | Class 900 | Class 1500 |

|---|---|---|---|---|---|

| Stainless Steel 316 | 285 psi | 740 psi | 1480 psi | 2220 psi | 3700 psi |

| Duplex 2205 | 290 psi | 750 psi | 1500 psi | 2250 psi | 3750 psi |

| Inconel 625 | 260 psi | 675 psi | 1350 psi | 2025 psi | 3375 psi |

| Hastelloy C276 | 270 psi | 710 psi | 1420 psi | 2130 psi | 3550 psi |

Weight Chart

Expanded Table (Custom Fabricated Reducers)

| NPS (Large End) | NPS (Small End) | Wall Thickness (mm) | Approx. Weight (kg) |

|---|---|---|---|

| 4" | 2" | 6.0 | 3.5 |

| 8" | 4" | 8.0 | 12.0 |

| 12" | 6" | 10.0 | 28.0 |

| 16" | 8" | 12.5 | 50.0 |

| 24" | 12" | 15.0 | 120.0 |

Tolerances

Expanded Table (Fabricated Fittings – as per ASME B16.9)

| Parameter | Tolerance |

|---|---|

| Outside Diameter (D) | ±1% or ±1.5 mm (whichever is greater) |

| Wall Thickness (t) | Not less than 87.5% of specified |

| Center-to-End (A) | ±3 mm (NPS ≤ 12"), ±5 mm (NPS > 12") |

| Angularity | ±0.5° |

| Straightness | 0.03 mm per mm |

Grades Available

Custom fabricated fittings are available in multiple grades for diverse industries:

| Material | Grades |

|---|---|

| Stainless Steel | 304, 304L, 316, 316L, 310, 321, 347 – for hygiene critical and corrosion resistant uses. |

| Carbon Steel | ASTM A234 WPB, ASTM A105, IS2062 – for structural and high pressure piping. |

| Duplex & Super Duplex | UNS S31803, S32205, S32750, S32760 – for offshore, marine, and chemical processing. |

| Nickel Alloys | Inconel 600/625/825, Monel 400/K500, Hastelloy C22/C276 – for extreme heat and corrosive service. |

| Titanium | Grades 1, 2, 5 – for aerospace, desalination, and medical industries. |

| Copper Alloys | Cu-Ni 70/30, Cu-Ni 90/10 – for marine, desalination, and shipbuilding applications. |

Applications

Custom Fabricated Fittings are crucial in projects where standard fittings are not suitable due to design constraints or operational demands.

Oil, Gas & Petrochemical

- Complex pipeline layouts for refineries and offshore platforms.

- Manifold assemblies, laterals, and special reducers for processing units.

- High pressure and high temperature fittings for critical flow lines.

Power Generation & Energy

- Fittings for boiler feed lines, condensers, and turbine systems.

- Custom elbows, tees, and reducers for nuclear, thermal, and renewable plants.

Marine & Shipbuilding

- Saltwater resistant fittings for ship piping, ballast systems, and offshore rigs.

- Large bore fabricated fittings for desalination plants and marine structures.

Automotive & Aerospace

- Precision fabricated fittings for fuel lines, exhaust systems, and hydraulic systems.

- Titanium and nickel alloy fittings for aerospace assemblies and prototypes.

Construction & Infrastructure

- Custom bends, headers, and Y-pieces for HVAC, fire protection, and water distribution systems.

- Structural and architectural fittings for stadiums, malls, and high rise projects.

Uses of Custom Fabricated Fittings

Custom Fabricated Fittings

Special Layouts

Enables complex piping designs not possible with standard fittings.

Project-Specific Needs

Tailored for unique pressures, temperatures, and flow requirements.

Repair & Replacement

Used for retrofit projects where older pipelines require non-standard fittings.

Heavy Duty Service

Handles harsh chemicals, seawater, and extreme conditions.

Design Flexibility

Allows architects and engineers to integrate fittings into challenging spaces.

Advantages of Custom Fabricated Fittings

Precision Engineering

Designed and fabricated to exact specifications.

Material Flexibility

Available in stainless, carbon, duplex, nickel, titanium, and copper alloys.

Cost Effective Solutions

Eliminates the need for multiple welded joints by providing a single-piece fitting.

Quick Turnaround

Custom solutions delivered faster than sourcing rare or imported parts.

Compliance

Manufactured as per ASTM, ASME, API, and international standards.

Enhanced Safety

Ensures proper flow, pressure handling, and leak proof integrity.

WHY CHOOSE US?

FAQ's

What are custom fabricated fittings?

Custom fabricated fittings are specially designed pipe fittings that are manufactured according to specific requirements, such as size, material, design, or application. They are used when standard fittings do not meet the needs of a project.

Which industries use custom fabricated fittings?

These fittings are widely used in oil & gas, petrochemical, power generation, marine, chemical processing, food & beverage, water treatment, and other industries where unique piping solutions are required.

What materials are available for custom fabricated fittings?

We offer fittings in stainless steel, duplex steel, super duplex, nickel alloys (Inconel, Hastelloy, Monel), titanium, copper alloys, and other high performance materials depending on the application.

What types of fittings can be custom fabricated?

Elbows, tees, reducers, crosses, stub ends, branch fittings, lateral fittings, headers, manifolds, and other complex pipe components can all be fabricated as per project needs.

How are custom fabricated fittings manufactured?

They are manufactured through advanced processes such as cutting, bending, welding, machining, and heat treatment to ensure precise dimensions, strength, and durability.

Contact Us

Need custom fabricated fittings for your pipeline or industrial project?

Contact

Moksh Tubes & Fittings LLP