-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

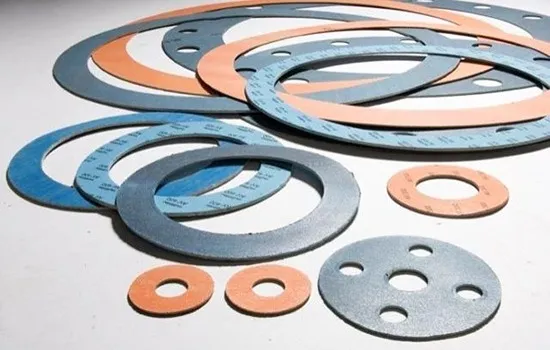

Flange & Industrial Gaskets

Gaskets are essential sealing components used to create a pressure tight seal between two or more mating surfaces, preventing leakage of liquids or gases under various operating conditions.

They are commonly installed between flanges and gaskets, valves, pumps, compressors, and other mechanical connections in industries where high pressure, temperature, and corrosive media are present.

Moksh Tubes & Fittings LLP, we supply a comprehensive range of industrial gaskets and seals – from standard flange gaskets, head gaskets, and rubber gaskets to custom engineered sealing solutions. We also provide PTFE gaskets, spiral wound gaskets, graphite gaskets, metal gaskets, and non asbestos gaskets.

Specifications

| Category | Details |

|---|---|

| Category |

Non Metallic (Rubber gaskets, PTFE gaskets, Non Asbestos gaskets, Graphite gaskets)

Semi Metallic (Spiral Wound gaskets, Corrugated, Kammprofile gaskets) Metallic (Stainless Steel gaskets, Soft Iron, Inconel) |

| Thickness | 0.5 mm to 12 mm (special thicknesses on request) |

| Sizes | ½” NB to 72” NB (custom gaskets available for large flanges & vessels) |

| Types | Spiral wound gaskets, Ring Type Joint (RTJ) gaskets, Metal Jacketed, Kammprofile gaskets, Soft Cut, Non-asbestos gaskets, Rubber gaskets, PTFE envelope gaskets |

| Pressure Class | Class 150 to Class 2500 / PN6 to PN400 |

Charts

Weight Chart

| Nominal Pipe Size (NPS) | Flange Class | Inside Diameter (ID) mm | Outside Diameter (OD) mm | Bolt Circle Dia. (BCD) mm | Number of Bolts | Bolt Hole Dia. mm |

|---|---|---|---|---|---|---|

| ½" (DN 15) | 150 | 21.3 | 47 | 35 | 4 | 16 |

| ¾" (DN 20) | 150 | 26.7 | 57 | 43 | 4 | 16 |

| 1" (DN 25) | 150 | 33.4 | 66 | 51 | 4 | 16 |

| 1 ½" (DN 40) | 150 | 48.3 | 82 | 73 | 4 | 16 |

| 2" (DN 50) | 150 | 60.3 | 104 | 92 | 4 | 19 |

| 2 ½" (DN 65) | 150 | 73 | 123 | 105 | 4 | 19 |

| 3" (DN 80) | 150 | 89 | 133 | 127 | 4 | 19 |

| 4" (DN 100) | 150 | 114 | 173 | 157 | 8 | 19 |

| 5" (DN 125) | 150 | 141 | 200 | 186 | 8 | 22 |

| 6" (DN 150) | 150 | 168 | 228 | 216 | 8 | 22 |

| 8" (DN 200) | 150 | 219 | 285 | 270 | 8 | 22 |

| 10" (DN 250) | 150 | 273 | 343 | 324 | 12 | 25 |

| 12" (DN 300) | 150 | 324 | 406 | 381 | 12 | 25 |

| 14" (DN 350) | 150 | 356 | 438 | 413 | 12 | 29 |

| 16" (DN 400) | 150 | 406 | 489 | 470 | 16 | 29 |

| 18" (DN 450) | 150 | 457 | 546 | 533 | 16 | 32 |

| 20" (DN 500) | 150 | 508 | 610 | 584 | 20 | 32 |

| 24" (DN 600) | 150 | 610 | 720 | 692 | 20 | 35 |

Ring Gaskets

Expanded Table (for class 150 – Ring Gaskets)

| Nominal Pipe Size (NPS) | Inside Diameter (ID) (mm) | Outside Diameter (OD) (mm) | Bolt Circle Diameter (mm) | Number of Bolts | Bolt Hole Diameter (mm) |

|---|---|---|---|---|---|

| ½″ | 21.3 | 47.6 | 34.9 | 4 | 15.9 |

| ¾″ | 26.7 | 57.2 | 44.5 | 4 | 15.9 |

| 1″ | 33.4 | 66.7 | 54.0 | 4 | 15.9 |

| 1¼″ | 42.2 | 76.2 | 63.5 | 4 | 15.9 |

| 1½″ | 48.3 | 85.7 | 73.0 | 4 | 15.9 |

| 2″ | 60.3 | 104.8 | 92.1 | 4 | 19.1 |

| 2½″ | 73.0 | 127.0 | 104.8 | 4 | 19.1 |

| 3″ | 88.9 | 146.1 | 127.0 | 4 | 19.1 |

| 4″ | 114.3 | 171.5 | 157.2 | 8 | 19.1 |

| 5″ | 141.3 | 196.9 | 185.7 | 8 | 22.2 |

| 6″ | 168.3 | 222.3 | 215.9 | 8 | 22.2 |

| 8″ | 219.1 | 279.4 | 269.9 | 8 | 22.2 |

| 10″ | 273.0 | 336.6 | 323.8 | 12 | 25.4 |

| 12″ | 323.8 | 393.7 | 381.0 | 12 | 25.4 |

| 14″ | 355.6 | 450.8 | 412.8 | 12 | 28.6 |

| 16″ | 406.4 | 514.4 | 469.9 | 16 | 28.6 |

| 18″ | 457.2 | 571.5 | 533.4 | 16 | 31.8 |

| 20″ | 508.0 | 628.7 | 584.2 | 20 | 31.8 |

| 24″ | 609.6 | 749.3 | 692.2 | 20 | 34.9 |

Gaskets

Expanded Table (for class 150 – 2500 )

| NPS (inch) | Inside Diameter (mm) | Outside Diameter (mm) | Bolt Circle Dia (mm) | No. of Bolts | Bolt Hole Dia (mm) | Thickness (mm) |

|---|---|---|---|---|---|---|

| ½ | 21.3 | 47 | 35 | 4 | 16 | 1.5 / 3.0 |

| ¾ | 26.7 | 60 | 44.5 | 4 | 16 | 1.5 / 3.0 |

| 1 | 33.4 | 70 | 51.0 | 4 | 16 | 1.5 / 3.0 |

| 1 ½ | 48.3 | 95 | 73.0 | 4 | 19 | 1.5 / 3.0 |

| 2 | 60.3 | 120 | 92.0 | 4 / 8 | 19 | 1.5 / 3.0 |

| 3 | 88.9 | 152 | 127.0 | 4 / 8 | 19 | 1.5 / 3.0 |

| 4 | 114.3 | 190 | 157.0 | 8 | 19 | 1.5 / 3.0 |

| 6 | 168.3 | 260 | 216.0 | 8 / 12 | 22 | 1.5 / 3.0 |

| 8 | 219.1 | 325 | 270.0 | 8 / 12 | 22 | 1.5 / 3.0 |

| 10 | 273.0 | 405 | 349.0 | 12 / 16 | 25 | 1.5 / 3.0 |

| 12 | 323.9 | 485 | 406.0 | 12 / 16 | 25 | 1.5 / 3.0 |

| 14 – 24 | As per ASME B16.5 | |||||

Grades Available

Gaskets is manufactured in a wide range of grades, ensuring suitability for different applications, environments, and design goals:

| Material | Grades / Details |

|---|---|

| Stainless Steel Grades | 304, 304L, 316,

316L (Used for spiral wound gaskets & metallic gaskets) |

| Alloys | Inconel, Monel, Hastelloy (For high temperature gaskets) |

| Soft Materials | Graphite gasket sheet, PTFE gasket sheet, Rubber gasket sheet, Cork gasket sheet, Foam gaskets |

| Specialty | Ceramic gaskets, Butyl gaskets, Polyurethane gaskets, EMI gaskets |

Applications

Gaskets is versatile and used across a variety of industries and settings:

Oil, Gas & Petrochemical

- RTJ gaskets

- Spiral wound gaskets

- Heat exchanger gaskets

Power Generation

- Boiler gaskets

- Steam gaskets

- Exhaust manifold gaskets

Marine & Shipbuilding

- Rubber gaskets

- PTFE gaskets

- Non-asbestos gaskets

Chemical Industry

- Graphite gaskets

- PTFE envelope gaskets

- Acid-resistant gaskets

Food & Pharma

- Silicone gaskets

- PTFE sanitary gaskets

Construction

- Pipe gaskets

- Rubber door gaskets

- Window gaskets

Uses of Gaskets

Gaskets are used extensively across multiple industries, including:

Leak Proof Sealing

Provide leak proof sealing between flange joints.

Flange Surface Compensation

Compensate for irregular flange faces effectively.

High Pressure & Temperature Resistance

Withstand high pressure gaskets and high temperature gaskets.

Easy Maintenance

Allow easy disassembly & maintenance.

Safety Assurance

Ensure safety in engine gaskets, automotive gaskets, and industrial sealing gaskets.

WHY CHOOSE US?

FAQ's

What is a gasket?

A gasket is a mechanical sealing component placed between two surfaces to prevent leakage of fluids or gases. Industrial gaskets are widely used in pipelines, heat exchangers, valves, and flanges to ensure a secure seal under high pressure and temperature.

Which gasket material is best?

The best gasket material depends on the application. Rubber gaskets work well for low-temperature sealing, PTFE gaskets are ideal for chemical resistance, while metal gaskets like spiral wound or ring-type joints are best for high-pressure, high-temperature environments.

What are the different types of gaskets?

Common types of gaskets include:

- Spiral Wound Gaskets

- Ring Type Joint (RTJ) Gaskets

- Graphite Gaskets

- PTFE Gaskets

- Rubber Gaskets

- Non-Asbestos Gaskets

How do I choose the right gasket for my project?

To select the right industrial gasket, consider factors like pressure, temperature, fluid type, and flange design. Consulting with experts like Mokshtubes Fittings LLP ensures you get the correct gasket material for long-term performance.

What industries use gaskets?

Gaskets are essential in industries such as oil & gas, petrochemicals, power generation, marine, pharmaceuticals, and food processing, where reliable sealing is critical to safety and efficiency.

Contact Us

Looking for gasket manufacturers in India or a reliable gasket supplier?

Contact Moksh Tubes & Fittings LLP