-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

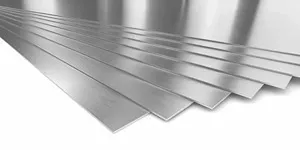

Cladded Plates

Cladded Plates are advanced composite materials created by bonding two or more different metals to combine their best properties. Typically, a corrosion resistant alloy (CRA) such as stainless steel, nickel alloy, or titanium is bonded to a structural backing material like carbon steel or low alloy steel.

This process results in a plate that offers the strength, cost-efficiency, and weldability of the base metal while providing the corrosion resistance, wear resistance, or heat resistance of the cladding layer.

Moksh Tubes & Fittings LLP, we supply high-quality cladded plates manufactured through explosive bonding, roll bonding, or weld overlay techniques. Our products comply with ASTM, ASME, API, and international standards, ensuring long lasting performance in aggressive environments like oil & gas, petrochemical, marine, and power generation industries.

Specifications

| Category | Details |

|---|---|

| Base Material (Backing Steel) | Carbon Steel (ASTM A516 Gr. 60/70, ASTM A36), Low Alloy Steel |

| Cladding Material | Stainless Steel, Duplex & Super Duplex, Nickel Alloys, Titanium, Copper Alloys |

| Thickness Range | 3 mm to 200 mm (total composite thickness) |

| Cladding Thickness | 1 mm to 25 mm (depending on requirement) |

| Plate Size | Up to 3,000 mm width × 12,000 mm length (custom sizes available) |

| Cladding Methods | Explosive Bonded, Roll Bonded, Weld Overlay |

| Standards | ASTM B898, ASME SA263, SA264, SA265, API clad plate standards |

| Finishes | Mill Finish, Pickled & Passivated, Polished |

Charts

Cladded Plate Weight Chart (kg/m²)

| Total Thickness (mm) | MS + SS Clad | MS + Copper Clad | MS + Brass Clad | SS + Aluminium Clad | SS + Copper Clad |

|---|---|---|---|---|---|

| 4 (3+1) | 31.4 | 32.1 | 31.9 | 29.5 | 32.5 |

| 5 (4+1) | 39.2 | 40.2 | 40.0 | 37.1 | 40.9 |

| 6 (5+1) | 47.1 | 48.4 | 48.2 | 44.8 | 49.4 |

| 8 (6+2) | 62.8 | 64.5 | 64.2 | 59.0 | 65.9 |

| 10 (8+2) | 78.5 | 80.6 | 80.2 | 73.8 | 82.4 |

| 12 (10+2) | 94.2 | 96.7 | 96.3 | 88.6 | 98.9 |

| 16 (12+4) | 125.6 | 129.0 | 128.5 | 118.1 | 132.0 |

| 20 (15+5) | 157.0 | 161.2 | 160.6 | 147.6 | 165.2 |

| 25 (20+5) | 196.3 | 201.5 | 200.9 | 184.5 | 206.7 |

| 30 (25+5) | 235.5 | 241.8 | 241.2 | 221.5 | 248.2 |

| 40 (30+10) | 314.0 | 322.4 | 321.6 | 295.2 | 331.0 |

| 50 (40+10) | 392.5 | 402.9 | 402.0 | 368.9 | 413.7 |

Grades Available

Cladded Plates are available in multiple combinations of base and clad materials, including

| Material | Grades / Clad Options |

|---|---|

| Stainless Steel Clad |

SS 304, 304L, 316,

316L, 321, 347 over carbon steel backing

(Corrosion resistance & chemical processing) |

| Duplex & Super Duplex Clad |

UNS S31803, S32750,

S32760 for offshore and harsh environments

(Oil, gas & offshore applications) |

| Nickel Alloy Clad |

Inconel 625, Inconel 825, Hastelloy

C22/C276 for chemical plants

(High temperature & corrosive service) |

| Titanium Clad |

Grades 1, 2, 5 for desalination and aerospace industries

(Aerospace & desalination projects) |

| Copper & Copper Nickel Clad |

Cu-Ni 70/30, Cu-Ni 90/10 for marine and shipbuilding use

(Marine & shipbuilding applications) |

| Special Alloys |

AL-6XN, Alloy 926, and other high performance metals for project specific

requirements

(High performance & custom applications) |

Applications

Cladded Plates are widely used in critical industries where strength, corrosion resistance, and cost efficiency are essential:

Construction & Infrastructure

- Cladded plates for structural support and corrosion resistance

Marine & Shipbuilding

- Cu-Ni, stainless, and duplex clads for seawater & marine environments

Oil, Gas & Petrochemical

- Nickel alloy, stainless, and duplex clads for pressure vessels, pipelines, and separators

Automotive & Aerospace

- Titanium and stainless clads for engine components, aerospace structural parts

Industrial Manufacturing

- Clad plates for heat exchangers, reactors, and machining stock

Decorative & Architectural

- Stainless and brass clads for architectural panels and luxury trims

Power Generation

- Cladded plates for boiler walls, condensers, and flue gas desulfurization systems

Defense & Aerospace

- Specialized clads for military equipment and aerospace structural parts

Uses of Cladded Plates

Cladded Plates are used extensively across multiple industries, including:

Cost Effective Corrosion Protection

Provides corrosion resistance at a lower cost than solid alloy plates

Extended Service Life

Extends the life of pressure vessels, tanks, and piping systems

Chemical & Marine Safety

Enables safe handling of aggressive chemicals and seawater

Strength with Alloy Protection

Reduces material costs by combining carbon steel strength with alloy protection

Reliable Long-Term Performance

Used in critical safety applications requiring durable, long-term reliability

Advantages of Cladded Plates

Cost Effective Solution

Alloy layer provides corrosion resistance without full-thickness alloy costs

Enhanced Strength

Structural integrity of carbon steel with surface durability of exotic alloys

Versatility

Available in a wide range of alloy combinations for multiple industries

Customizable

Tailored cladding thickness and plate dimensions

Sustainability

Reduces waste of expensive materials while delivering top-tier performance

Compliance with Global Standards

Manufactured as per ASTM, ASME, and API requirements

Frequently Asked Questions (FAQ) – Cladded Plates

What are cladded plates?

Cladded plates are composite plates made by bonding two or more different metals together. Typically, a corrosion-resistant metal (like stainless steel or nickel alloy) is bonded to a strong carbon steel or alloy steel base to combine strength and corrosion resistance.

Which materials are used for cladded plates?

Base Metals: Carbon steel, alloy steel

Cladding Metals: Stainless steel (304, 316, 316L), Nickel alloys, Titanium, Duplex &

Super Duplex, Copper alloys

What are the common bonding methods for cladded plates?

Explosion Welding – high energy bonding for dissimilar metals

Roll Bonding – mechanical bonding via high pressure

Bimetallic Casting – molten metal bonding

Other specialized welding techniques depending on application

What thickness range is available in cladded plates?

Base Metal: typically 6 mm to 150 mm

Cladding Layer: typically 1 mm to 15 mm

(Custom thicknesses can be provided as per requirement)

What are the common applications of cladded plates?

Chemical processing and storage tanks

Petrochemical and refinery equipment

Heat exchangers and pressure vessels

Marine and offshore structures

Power generation equipment

WHY CHOOSE US?

Contact Us

Looking for Cladded Plates that deliver strength, corrosion resistance, and cost-efficiency?

Contact

Moksh Tubes & Fittings LLP