-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

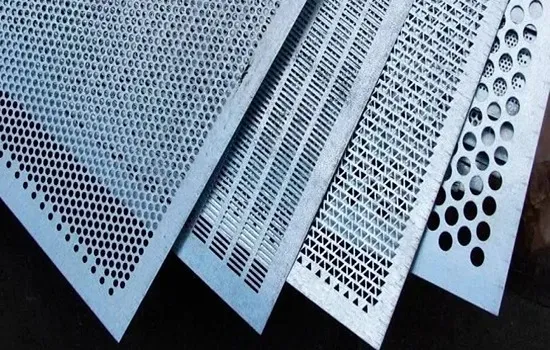

Perforated Sheets

Perforated Sheets are metal sheets that have been punched or stamped with a pattern of holes, slots, or decorative shapes. These sheets serve a functional purpose (such as filtration, ventilation, soundproofing, or screening) while also offering decorative appeal for architectural and design applications.

Manufactured from stainless steel, mild steel, aluminum, copper, and specialty alloys, perforated sheets are available in a variety of hole sizes, patterns, and thicknesses. Moksh Tubes & Fittings LLP provides premium quality perforated sheets with precise punching, uniform spacing, and clean edges manufactured to ASTM, ASME, DIN, EN, and IS standards. Our sheets are widely used in industrial, architectural, acoustic, and filtration systems worldwide.

Specifications

| Category | Details |

|---|---|

| Material | Stainless Steel, Carbon Steel, Mild Steel, Aluminum, Brass, Copper, Titanium |

| Grades | ASTM/ASME/EN/IS certified grades |

| Thickness Range | 0.3 mm to 12 mm |

| Sheet Size | Standard: 1000 × 2000 mm, 1220 × 2440 mm, 1500 × 3000 mm (custom sizes available) |

| Hole Patterns | Round, Square, Slotted, Hexagonal, Oblong, Decorative |

| Hole Sizes | 0.5 mm to 50 mm (custom punching available) |

| Finishes | Mill Finish, Polished, Anodized, Powder Coated |

| Standards | ASTM A240, A480, IS 6911, JIS G4304, EN 10088 |

| Applications | Architectural design, industrial screening, acoustic control, filtration |

Charts

Perforated Sheets Weight Chart MS (Mild Steel)

| Thickness (mm) | Plain kg/m² | 20% OA | 30% OA | 40% OA | 50% OA |

|---|---|---|---|---|---|

| 0.1 | 0.785 | 0.628 | 0.549 | 0.471 | 0.393 |

| 0.2 | 1.570 | 1.256 | 1.099 | 0.942 | 0.785 |

| 0.3 | 2.355 | 1.884 | 1.648 | 1.413 | 1.177 |

| 0.4 | 3.140 | 2.512 | 2.198 | 1.884 | 1.570 |

| 0.5 | 3.925 | 3.140 | 2.747 | 2.355 | 1.962 |

| 0.6 | 4.710 | 3.768 | 3.297 | 2.826 | 2.355 |

| 0.8 | 6.280 | 5.024 | 4.396 | 3.768 | 3.140 |

| 1.0 | 7.850 | 6.280 | 5.495 | 4.710 | 3.925 |

| 1.2 | 9.420 | 7.536 | 6.594 | 5.652 | 4.710 |

| 1.5 | 11.775 | 9.420 | 8.242 | 7.065 | 5.888 |

| 2.0 | 15.700 | 12.560 | 10.990 | 9.420 | 7.850 |

| 2.5 | 19.625 | 15.700 | 13.738 | 11.775 | 9.813 |

| 3.0 | 23.550 | 18.840 | 16.485 | 14.130 | 11.775 |

| 3.5 | 27.475 | 21.980 | 19.233 | 16.485 | 13.738 |

| 4.0 | 31.400 | 25.120 | 21.980 | 18.840 | 15.700 |

| 5.0 | 39.250 | 31.400 | 27.475 | 23.550 | 19.625 |

| 6.0 | 47.100 | 37.680 | 32.970 | 28.260 | 23.550 |

| 8.0 | 62.800 | 50.240 | 43.960 | 37.680 | 31.400 |

| 10.0 | 78.500 | 62.800 | 54.950 | 47.100 | 39.250 |

| 12.0 | 94.200 | 75.360 | 65.940 | 56.520 | 47.100 |

| 15.0 | 117.750 | 94.200 | 82.425 | 70.650 | 58.875 |

| 16.0 | 125.600 | 100.480 | 87.920 | 75.360 | 62.800 |

| 18.0 | 141.300 | 113.040 | 98.910 | 84.780 | 70.650 |

| 20.0 | 157.000 | 125.600 | 109.900 | 94.200 | 78.500 |

Perforated Sheets Weight Chart SS (Stainless Steel)

| Thickness (mm) | Plain kg/m² | 20% OA | 30% OA | 40% OA | 50% OA |

|---|---|---|---|---|---|

| 0.1 | 0.793 | 0.634 | 0.555 | 0.476 | 0.397 |

| 0.2 | 1.586 | 1.269 | 1.110 | 0.952 | 0.793 |

| 0.3 | 2.379 | 1.903 | 1.665 | 1.427 | 1.189 |

| 0.4 | 3.172 | 2.538 | 2.220 | 1.903 | 1.586 |

| 0.5 | 3.965 | 3.172 | 2.776 | 2.379 | 1.982 |

| 0.6 | 4.758 | 3.806 | 3.331 | 2.855 | 2.379 |

| 0.8 | 6.344 | 5.075 | 4.441 | 3.807 | 3.172 |

| 1.0 | 7.930 | 6.344 | 5.551 | 4.758 | 3.965 |

| 1.2 | 9.516 | 7.613 | 6.661 | 5.709 | 4.758 |

| 1.5 | 11.895 | 9.516 | 8.327 | 7.137 | 5.948 |

| 2.0 | 15.860 | 12.688 | 11.102 | 9.516 | 7.930 |

| 2.5 | 19.825 | 15.860 | 13.878 | 11.895 | 9.913 |

| 3.0 | 23.790 | 19.032 | 16.653 | 14.274 | 11.895 |

| 3.5 | 27.755 | 22.204 | 19.429 | 16.653 | 13.877 |

| 4.0 | 31.720 | 25.376 | 22.204 | 19.032 | 15.860 |

| 5.0 | 39.650 | 31.720 | 27.755 | 23.790 | 19.825 |

| 6.0 | 47.580 | 38.064 | 33.306 | 28.548 | 23.790 |

| 8.0 | 63.440 | 50.752 | 44.408 | 38.064 | 31.720 |

| 10.0 | 79.300 | 63.440 | 55.510 | 47.580 | 39.650 |

| 12.0 | 95.160 | 76.128 | 66.612 | 57.096 | 47.580 |

| 15.0 | 118.950 | 95.160 | 83.265 | 71.370 | 59.475 |

| 16.0 | 126.880 | 101.504 | 88.816 | 76.128 | 63.440 |

| 18.0 | 142.740 | 114.192 | 99.918 | 85.644 | 71.370 |

| 20.0 | 158.600 | 126.880 | 111.020 | 95.160 | 79.300 |

Perforated Sheets Weight Chart (Aluminum)

| Thickness (mm) | Plain kg/m² | 20% OA | 30% OA | 40% OA | 50% OA |

|---|---|---|---|---|---|

| 0.1 | 0.270 | 0.216 | 0.189 | 0.162 | 0.135 |

| 0.2 | 0.540 | 0.432 | 0.378 | 0.324 | 0.270 |

| 0.3 | 0.810 | 0.648 | 0.567 | 0.486 | 0.405 |

| 0.4 | 1.080 | 0.864 | 0.756 | 0.648 | 0.540 |

| 0.5 | 1.350 | 1.080 | 0.945 | 0.810 | 0.675 |

| 0.6 | 1.620 | 1.296 | 1.134 | 0.972 | 0.810 |

| 0.8 | 2.160 | 1.728 | 1.512 | 1.296 | 1.080 |

| 1.0 | 2.700 | 2.160 | 1.890 | 1.620 | 1.350 |

| 1.2 | 3.240 | 2.592 | 2.268 | 1.944 | 1.620 |

| 1.5 | 4.050 | 3.240 | 2.835 | 2.430 | 2.025 |

| 2.0 | 5.400 | 4.320 | 3.780 | 3.240 | 2.700 |

| 2.5 | 6.750 | 5.400 | 4.725 | 4.050 | 3.375 |

| 3.0 | 8.100 | 6.480 | 5.670 | 4.860 | 4.050 |

| 3.5 | 9.450 | 7.560 | 6.615 | 5.670 | 4.725 |

| 4.0 | 10.800 | 8.640 | 7.560 | 6.480 | 5.400 |

| 5.0 | 13.500 | 10.800 | 9.450 | 8.100 | 6.750 |

| 6.0 | 16.200 | 12.960 | 11.340 | 9.720 | 8.100 |

| 8.0 | 21.600 | 17.280 | 15.120 | 12.960 | 10.800 |

| 10.0 | 27.000 | 21.600 | 18.900 | 16.200 | 13.500 |

| 12.0 | 32.400 | 25.920 | 22.680 | 19.440 | 16.200 |

| 15.0 | 40.500 | 32.400 | 28.350 | 24.300 | 20.250 |

| 16.0 | 43.200 | 34.560 | 30.240 | 25.920 | 21.600 |

| 18.0 | 48.600 | 38.880 | 34.020 | 29.160 | 24.300 |

| 20.0 | 54.000 | 43.200 | 37.800 | 32.400 | 27.000 |

Perforated Sheets Weight Chart (Brass)

| Thickness (mm) | Plain kg/m² | 20% OA | 30% OA | 40% OA | 50% OA |

|---|---|---|---|---|---|

| 0.1 | 0.840 | 0.672 | 0.588 | 0.504 | 0.420 |

| 0.2 | 1.680 | 1.344 | 1.176 | 1.008 | 0.840 |

| 0.3 | 2.520 | 2.016 | 1.764 | 1.512 | 1.260 |

| 0.4 | 3.360 | 2.688 | 2.352 | 2.016 | 1.680 |

| 0.5 | 4.200 | 3.360 | 2.940 | 2.520 | 2.100 |

| 0.6 | 5.040 | 4.032 | 3.528 | 3.024 | 2.520 |

| 0.8 | 6.720 | 5.376 | 4.704 | 4.032 | 3.360 |

| 1.0 | 8.400 | 6.720 | 5.880 | 5.040 | 4.200 |

| 1.2 | 10.080 | 8.064 | 7.056 | 6.048 | 5.040 |

| 1.5 | 12.600 | 10.080 | 8.820 | 7.560 | 6.300 |

| 2.0 | 16.800 | 13.440 | 11.760 | 10.080 | 8.400 |

| 2.5 | 21.000 | 16.800 | 14.700 | 12.600 | 10.500 |

| 3.0 | 25.200 | 20.160 | 17.640 | 15.120 | 12.600 |

| 3.5 | 29.400 | 23.520 | 20.580 | 17.640 | 14.700 |

| 4.0 | 33.600 | 26.880 | 23.520 | 20.160 | 16.800 |

| 5.0 | 42.000 | 33.600 | 29.400 | 25.200 | 21.000 |

| 6.0 | 50.400 | 40.320 | 35.280 | 30.240 | 25.200 |

| 8.0 | 67.200 | 53.760 | 47.040 | 40.320 | 33.600 |

| 10.0 | 84.000 | 67.200 | 58.800 | 50.400 | 42.000 |

| 12.0 | 100.800 | 80.640 | 70.560 | 60.480 | 50.400 |

| 15.0 | 126.000 | 100.800 | 88.200 | 75.600 | 63.000 |

| 16.0 | 134.400 | 107.520 | 94.080 | 80.640 | 67.200 |

| 18.0 | 151.200 | 120.960 | 105.840 | 90.720 | 75.600 |

| 20.0 | 168.000 | 134.400 | 117.600 | 100.800 | 84.000 |

Perforated Sheets Weight Chart (Copper)

| Thickness (mm) | Plain kg/m² | 20% OA | 30% OA | 40% OA | 50% OA |

|---|---|---|---|---|---|

| 0.1 | 0.894 | 0.715 | 0.626 | 0.536 | 0.447 |

| 0.2 | 1.788 | 1.430 | 1.252 | 1.073 | 0.894 |

| 0.3 | 2.682 | 2.146 | 1.877 | 1.609 | 1.341 |

| 0.4 | 3.576 | 2.861 | 2.503 | 2.146 | 1.788 |

| 0.5 | 4.470 | 3.576 | 3.129 | 2.682 | 2.235 |

| 0.6 | 5.364 | 4.291 | 3.755 | 3.218 | 2.682 |

| 0.8 | 7.152 | 5.722 | 5.006 | 4.291 | 3.576 |

| 1.0 | 8.940 | 7.152 | 6.258 | 5.364 | 4.470 |

| 1.2 | 10.728 | 8.582 | 7.509 | 6.437 | 5.364 |

| 1.5 | 13.410 | 10.728 | 9.387 | 8.046 | 6.705 |

| 2.0 | 17.880 | 14.304 | 12.516 | 10.728 | 8.940 |

| 2.5 | 22.350 | 17.880 | 15.645 | 13.410 | 11.175 |

| 3.0 | 26.820 | 21.456 | 18.774 | 16.092 | 13.410 |

| 3.5 | 31.290 | 25.032 | 21.903 | 18.774 | 15.645 |

| 4.0 | 35.760 | 28.608 | 25.032 | 21.456 | 17.880 |

| 5.0 | 44.700 | 35.760 | 31.290 | 26.820 | 22.350 |

| 6.0 | 53.640 | 42.912 | 37.548 | 32.184 | 26.820 |

| 8.0 | 71.520 | 57.216 | 50.064 | 42.912 | 35.760 |

| 10.0 | 89.400 | 71.520 | 62.580 | 53.640 | 44.700 |

| 12.0 | 107.280 | 85.824 | 75.096 | 64.368 | 53.640 |

| 15.0 | 134.100 | 107.280 | 93.870 | 80.460 | 67.050 |

| 16.0 | 142.560 | 114.048 | 99.792 | 85.536 | 71.280 |

| 18.0 | 160.920 | 128.736 | 112.644 | 96.552 | 80.460 |

| 20.0 | 178.800 | 143.040 | 125.160 | 107.280 | 89.400 |

Grades Available

Perforated sheets are produced in a wide range of materials to suit diverse applications:

| Material | Grades / Uses |

|---|---|

| Stainless Steel | 304, 304L, 316, 316L, 321 – for hygiene critical, corrosion resistant uses |

| Carbon & Mild Steel | IS2062, ASTM A36 – for structural and industrial needs |

| Aluminum | 1100, 3003, 5052, 6061 – lightweight, corrosion resistant, and aesthetic |

| Copper & Brass | Decorative and functional use in interiors, facades, and ventilation panels |

| Titanium & Special Alloys | For aerospace, medical, and chemical process industries |

Types of Perforated Sheets

Round Hole Perforated Sheets

The most common, used for ventilation, filtration, and screens.

Square Hole Perforated Sheets

Provide an open and modern look for architecture and design.

Slotted Hole Perforated Sheets

Ideal for drainage, sieving, and sorting operations.

Hexagonal & Decorative Patterns

Used for facades, partitions, and artistic installations.

Applications

Perforated Sheets are versatile and used across industries:

Architecture & Interior Design

- Facades, ceilings, sunshades, wall claddings

Industrial Use

- Sieves, screens, filters, protective covers

Food Processing & Pharma

- Sanitary perforated trays, baskets, and filters

Automotive & Transport

- Grilles, ventilation covers, and soundproofing

Acoustics & Noise Control

- Acoustic panels, speaker grilles, sound barriers

HVAC & Ventilation

- Air diffusers, vents, and duct screens

Uses of Perforated Sheets

Perforated Sheets are used extensively across multiple industries, including:

Improves Airflow & Ventilation

Enhances circulation in industrial and architectural projects

Filtration Applications

Provides filtration for liquids, gases, and solids

Architectural Design

Enhances aesthetic appeal in facades and interiors

Acoustic Applications

Reduces noise levels with perforated panels & barriers

Lightweight & Durable

Strong yet lightweight for structural uses

Advantages of Perforated Sheets

Versatile & Functional

Suitable for industrial and decorative applications

Lightweight & Durable

Reduces weight while maintaining strength

Cost-Effective

Economical alternative to fully fabricated panels

Customizable

Available in custom hole sizes, shapes, and spacing

Corrosion Resistance

Especially when produced in stainless steel or aluminum

Complies with Global Standards

ASTM, ASME, EN, and DIN

Frequently Asked Questions (FAQ) – Perforated Sheets

What are perforated sheets?

Perforated sheets are metal sheets that have been punched or stamped with holes, slots, or decorative patterns. They are used for filtration, screening, ventilation, and aesthetic applications.

Which materials are perforated sheets available in?

They can be manufactured in stainless steel, carbon steel, aluminum, brass, copper, titanium, nickel alloys, and galvanized steel depending on the application.

What thickness range is offered for perforated sheets?

Perforated sheets are usually available in thicknesses from 0.3 mm to 12 mm, with customized options available on request.

What are the standard hole shapes and patterns?

- Round holes (most common)

- Square holes

- Slotted holes (rectangular/oblong)

- Hexagonal holes

- Decorative patterns (custom designs possible)

What are the typical applications of perforated sheets?

- Filtration and sieving

- Ventilation and air-conditioning grills

- Soundproofing and acoustic panels

- Sunshades and decorative facades

- Machinery guards and protective covers

- Food processing and chemical industries

WHY CHOOSE US?

Contact Us

Looking for high-quality Perforated Sheets for your industrial or architectural needs?

Contact

Moksh Tubes & Fittings LLP