-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

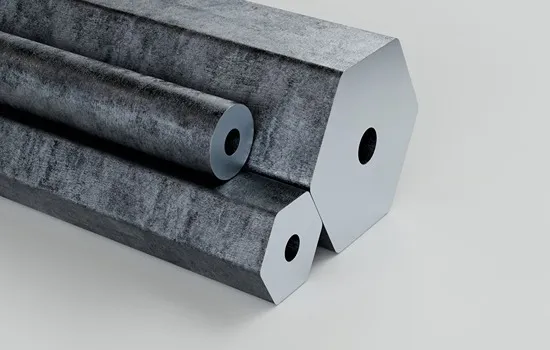

Hollow Bars

Hollow Bars are tubular metal bars with a hollow center, offering a high strength to weight ratio. Widely used in automotive, construction, marine, aerospace, and mechanical applications, they provide excellent machinability and versatility.

Moksh Tubes & Fittings LLP, we supply high quality stainless steel hollow bars, MS hollow bars, 4140 hollow bars, aluminium hollow square bars, bronze hollow bars, and nickel hollow bars. We also offer hollow square bars, extruded hollow bars, and oil filled hollow bars for specialized applications. All products conform to ASTM, ASME, DIN, EN, and JIS standards.

Specifications

| Category | Details |

|---|---|

| Material | Stainless Steel, Carbon Steel, Alloy Steel, Duplex & Super Duplex, Nickel Alloys, Titanium, Copper Alloys |

| Grades | ASTM, ASME, DIN, EN certified grades – all major alloys available |

| Size Range | OD: 25 mm – 450 mm / ID: 12 mm – 300 mm (custom sizes available) |

| Wall Thickness | 5 mm – 100 mm |

| Lengths | Standard 3m – 6m; cut to length on request |

| Standards | ASTM A511, A312, A790, EN 10294, DIN 17458 |

| Forms | Seamless Hollow Bars, Welded Hollow Bars |

| Finishes | Mill Finish, Polished, Pickled & Passivated, Ground |

Charts

Weight Chart

| OD (mm) | WT (mm) | ID (mm) | Weight (Kg/m) |

|---|---|---|---|

| 20 | 2 | 16 | 0.94 |

| 25 | 3 | 19 | 1.72 |

| 30 | 4 | 22 | 2.72 |

| 40 | 5 | 30 | 4.56 |

| 50 | 6 | 38 | 6.80 |

| 60 | 8 | 44 | 10.84 |

| 80 | 10 | 60 | 18.24 |

| 100 | 12 | 76 | 27.28 |

| 150 | 16 | 118 | 54.40 |

| 200 | 20 | 160 | 88.80 |

| 250 | 25 | 200 | 138.00 |

| 300 | 30 | 240 | 198.00 |

Nominal Bore

Expanded Table (for one item – Hollow Pipes)

| NB (mm) | Inches | OD (mm) | Sch 40 WT (mm) | Sch 40 Wt (Kg/m) | Sch 80 WT (mm) | Sch 80 Wt (Kg/m) |

|---|---|---|---|---|---|---|

| 15 | 1/2 | 21.3 | 2.77 | 1.27 | 3.73 | 1.62 |

| 20 | 3/4 | 26.7 | 2.87 | 1.68 | 3.91 | 2.20 |

| 25 | 1 | 33.4 | 3.38 | 2.50 | 4.55 | 3.24 |

| 32 | 1 1/4 | 42.2 | 3.56 | 3.38 | 4.85 | 4.47 |

| 40 | 1 1/2 | 48.3 | 3.68 | 4.05 | 5.08 | 5.41 |

| 50 | 2 | 60.3 | 3.91 | 5.44 | 5.54 | 7.48 |

| 65 | 2 1/2 | 73.0 | 5.16 | 8.63 | 7.01 | 11.40 |

| 80 | 3 | 88.9 | 5.49 | 11.30 | 7.62 | 15.20 |

| 100 | 4 | 114.3 | 6.02 | 16.07 | 8.56 | 22.30 |

| 150 | 6 | 168.3 | 7.11 | 28.30 | 10.97 | 42.70 |

| 200 | 8 | 219.1 | 8.18 | 42.60 | 12.70 | 64.60 |

| 250 | 10 | 273.1 | 9.27 | 60.50 | 12.70 | 96.00 |

| 300 | 12 | 323.9 | 9.52 | 73.88 | 12.70 | 132.00 |

Square Hollow Sections

| Size (mm) | WT (mm) | Weight (Kg/m) |

|---|---|---|

| 25 × 25 | 2 | 1.47 |

| 25 × 25 | 3 | 2.13 |

| 40 × 40 | 3 | 3.55 |

| 50 × 50 | 3 | 4.49 |

| 50 × 50 | 4 | 5.84 |

| 60 × 60 | 4 | 7.11 |

| 75 × 75 | 5 | 11.05 |

| 100 × 100 | 5 | 14.87 |

| 150 × 150 | 6 | 26.65 |

| 200 × 200 | 8 | 47.19 |

Rectangular Hollow Sections

| Size (mm) | WT (mm) | Weight (Kg/m) |

|---|---|---|

| 40 × 20 | 2 | 2.08 |

| 50 × 25 | 3 | 3.61 |

| 60 × 40 | 3 | 4.49 |

| 80 × 40 | 4 | 7.56 |

| 100 × 50 | 4 | 9.28 |

| 120 × 60 | 5 | 14.25 |

| 150 × 100 | 6 | 21.88 |

| 200 × 100 | 8 | 33.98 |

| 250 × 150 | 8 | 48.45 |

| 300 × 200 | 10 | 85.00 |

Oval Hollow Sections

| Size (mm) | WT (mm) | Weight (Kg/m) |

|---|---|---|

| 30 × 15 | 2 | 1.15 |

| 40 × 20 | 2 | 1.60 |

| 50 × 25 | 2.5 | 2.40 |

| 60 × 30 | 3 | 3.50 |

| 80 × 40 | 3 | 4.80 |

| 100 × 50 | 4 | 7.20 |

| 120 × 60 | 5 | 11.20 |

| 150 × 75 | 6 | 19.50 |

Grades Available

Hollow Bars is manufactured in a wide range of grades, ensuring suitability for different applications, environments, and design goals:

| Material | Grades |

|---|---|

| Stainless Steel | 304,

304L, 316, 316L, 310,

321, 347

(Corrosion resistance & machining) |

| Carbon Steel | ASTM A105, A350 LF2, IS2062 (Structural & general engineering) |

| Alloy Steel | 4140,

4130, EN19, EN24

(High strength machined components) |

| Duplex & Super Duplex | 2205,

S32750, S32760

(Offshore & chemical processing) |

| Nickel Alloys | Inconel, Monel, Hastelloy (High temperature & corrosive environments) |

| Titanium | Grades 2, 5 (Aerospace, desalination & chemical industries) |

| Copper Alloys | Cu-Ni

70/30, Cu-Ni 90/10, Brass, Bronze (Marine & decorative) |

Applications

Hollow Bars is versatile and used across a variety of industries and settings:

Construction & Infrastructure

- Structural supports, frameworks, base plates

Marine & Offshore

- Bronze, nickel, duplex, and Cu-Ni hollow bars for shafts, propellers, offshore rigs

Oil, Gas & Petrochemical

- Valve bodies, pump housings, manifolds, high-pressure pipelines

Industrial & Engineering

- Bushings, bearings, hydraulic cylinders, rollers, machine tools

Automotive & Aerospace

- Shafts, hydraulic systems, landing gear, lightweight components

Food, Pharma & Chemical

- Sanitary fittings, clean piping, processing machinery

Advantages of Hollow Bars

High Machinability

Turning, boring, threading, milling.

Consistent Quality

Tight tolerances on OD, ID, wall thickness.

Material Efficiency

Less waste, cost effective production.

Wide Material Range

Stainless, Duplex, Nickel, Titanium, Copper alloys.

Global Standards

ASTM, ASME, DIN, EN, ISO certified.

Custom Solutions

Cut to length & special dimensions available.

WHY CHOOSE US?

FAQ's

What is a hollow bar and where is it used?

A hollow bar is a metal bar with a hollow center, reducing weight while maintaining strength. It is widely used in construction, automotive, aerospace, marine, and mechanical projects.

What materials are available?

Stainless steel, MS, 4140, aluminium hollow square bars, bronze, and nickel hollow bars.

What sizes can I get?

Sizes range from 10 mm hollow bar to 2 inch × 2 inch hollow square bar, with wall thickness and custom diameters available.

Can I get hollow bars in Dhaka or Albany?

Yes, delivery is available for Hollow Square Bars in Dhaka, Hollow Bar Albany, and worldwide.

What types do you supply?

We supply hollow steel bar, extruded hollow bar, oil-filled hollow bar, MS hollow bar, and aluminium hollow square bar. All products meet ASTM, ASME, DIN, and EN standards.

Contact Us

For precision hollow bars for machining or structural applications:

Contact Moksh Tubes & Fittings LLP