In any industrial or manufacturing setting, efficiency is the engine of profitability. Every decision, from process design to material selection, is scrutinized for its potential to reduce costs, minimize downtime, and maximize output. While large machinery and automated systems often get the spotlight, the seemingly simple components, like pipes and tubes, play an equally critical role. The right tubing material can be the difference between a smooth, continuous operation and a system plagued by constant interruptions and maintenance.

Welcome to Moksh Tubes & Fittings LLP

Monday - Friday : 8:00 AM to 7:00 PM

-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

How Stainless Steel Tubes Improve Process Efficiency

How Stainless Steel Tubes Improve Process Efficiency

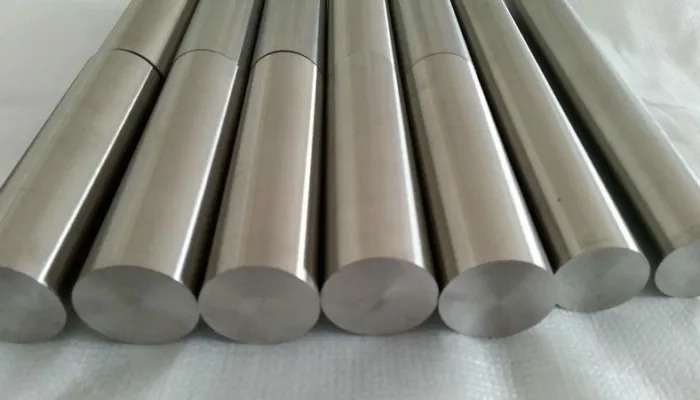

Stainless steel tubes have emerged as a key enabler of industrial process optimization. Their unique combination of properties goes far beyond simply transporting fluids; they actively contribute to a more efficient, reliable, and cost effective operation. This article will explore the specific ways stainless steel tubes enhance process efficiency, from reducing maintenance downtime to improving product quality and system longevity.

Stainless Steel Properties for Industrial Efficiency

To understand how stainless steel tubes boost efficiency, we first need to look at their inherent characteristics. These properties work together to create a material that solves many of the common challenges faced in industrial environments.

Unmatched Corrosion Resistance

The primary advantage of stainless steel is its built in defense against rust and corrosion. The chromium in the alloy forms a passive, self healing oxide layer that protects the metal from chemical attack and environmental degradation.

- How this boosts efficiency: Systems built with stainless steel do not suffer from the gradual thinning and weakening caused by rust. This eliminates the risk of leaks, contamination, and catastrophic failures that can halt production for days or weeks. The system maintains its integrity, ensuring a consistent and reliable flow.

Exceptional Durability and Strength

Stainless steel is a robust material capable of withstanding high pressures, extreme temperatures, and significant mechanical stress. Grades like Duplex stainless steel offer even higher strength, allowing for more demanding applications.

- How this boosts efficiency: The strength of stainless steel tubes means they are less susceptible to damage from vibration, impact, or pressure surges. This durability translates into fewer repairs and replacements. A system that doesn't break down is a system that keeps running, directly contributing to higher overall equipment effectiveness (OEE).

Low Maintenance Requirements

Unlike materials like carbon steel that require painting, coating, and constant inspection for rust, stainless steel is remarkably low maintenance. Its corrosion resistance is inherent, not a temporary coating.

- How this boosts efficiency: Reduced maintenance means less scheduled downtime and fewer labor hours dedicated to upkeep. Instead of shutting down a line to repair a corroded pipe, your team can focus on production and process improvement. This leads to significant long term cost savings and increased operational availability.

Superior Hygienic Properties

The surface of stainless steel is non porous, smooth, and easy to clean. It does not harbor bacteria or allow for the buildup of contaminants.

- How this boosts efficiency: In industries like food and beverage or pharmaceuticals, cleaning cycles are a major part of the production schedule. The ease of cleaning stainless steel known as its "cleanability" allows for faster and more effective sanitation. This reduces the time needed for clean in place (CIP) cycles, shortening the changeover time between production batches and increasing throughput.

Practical Examples of Stainless Steel Driving Efficiency

Let's move from theory to practice. Here are specific examples of how stainless steel tubes create tangible efficiency gains in real world industrial applications

Heat Exchangers: Maximizing Thermal Transfer

Heat exchangers are critical for controlling process temperatures in chemical plants, refineries, and power generation. Efficiency here is measured by how effectively heat is transferred from one fluid to another.

- The Stainless Steel Advantage: Stainless steel tubes are ideal for heat exchangers due to their excellent thermal conductivity and corrosion resistance. They can handle high temperatures and aggressive fluids without fouling or degrading. Because the tube walls remain clean and free from insulating layers of rust, heat transfer remains consistently high over the long term. This means less energy is required to achieve the desired heating or cooling, directly reducing operational costs.

Fluid Transport: Ensuring Uninterrupted Flow

Whether transporting water, chemicals, or slurries, the goal is to move the product from point A to point B with minimal friction and no loss.

- The Stainless Steel Advantage: The smooth interior surface of stainless steel tubes minimizes frictional losses, meaning less pumping energy is required to move fluids through the system. More importantly, because the pipes do not corrode, there is no risk of rust particles (scale) breaking off and clogging filters, valves, or sensitive equipment downstream. This prevents costly process interruptions and protects valuable machinery from damage, ensuring the entire system runs smoothly.

Food and Beverage Processing: Accelerating Production Cycles

In food and beverage manufacturing, efficiency is tied directly to hygiene and batch changeover speed.

- The Stainless Steel Advantage: The hygienic properties of food-grade stainless steel tubing (like grades 304 and 316) are paramount. The non-porous surface prevents product residue and microbial growth, allowing for rapid and effective cleaning between batches. A faster, more reliable cleaning process means less downtime. This allows manufacturers to produce a wider variety of products on the same line in a single day, dramatically improving asset utilization and overall plant efficiency.

High Purity Systems: Protecting Product Integrity

In industries like pharmaceuticals and semiconductors, even microscopic contamination can ruin an entire batch, leading to massive financial losses.

- The Stainless Steel Advantage: High purity stainless steel tubing is electropolished to create an incredibly smooth, inert surface. This prevents any particles from the tube itself from leaching into the high purity gases or liquids being transported. By guaranteeing product purity and eliminating contamination related batch failures, stainless steel provides the ultimate process security and efficiency.

The Verdict: A Strategic Investment in Performance

Stainless steel tubes are more than just a conduit; they are an active component in building a more efficient and profitable industrial process. By choosing stainless steel, you are making a strategic decision to reduce downtime, lower maintenance costs, save energy, and improve product quality.

While the initial purchase price may be higher than that of alternative materials like carbon steel, the long-term return on investment is undeniable. The benefits of stainless steel pipes compound over time, leading to a significantly lower total cost of ownership and a more resilient, reliable, and efficient operation. This makes stainless steel not a cost, but an investment in long-term industrial process optimization.

Ready to enhance the efficiency of your operations? Mokshtubes offers a comprehensive range of high-quality stainless steel tubes engineered for reliability and performance in the most demanding industrial environments. Contact our team of experts to discuss your application and discover how our solutions can help you achieve your efficiency goals.

Recent Blogs

-

Hastelloy C276 vs Inconel 625 | Best Alloy for Chemical Plants

February 03, 2026

Locate Us

info@mokstubes.com

Office Address: Hinglaj Bhavan, Gulalwadi Mumbai, Maharashtra. 400004

Office Address: 6/A, Ground Floor, Rajwanti Mansion, Khetwadi Mumbai

Office Address: 95/95A, Dawood Baug, Sukhlaji Street, Kamatipura Mumbai

Office Address: 92E, Plot No. 3, New Tank Bunder, Darukhana, Mumbai, Maharashtra- 400 010.

get in touch

Let’s forge a connection — contact our team today.

Contact Us

At Moksh Tubes & Fittings LLP, we’re dedicated to making your purchases seamless — offering expert advice, a wide inventory of certified products, and global support for every order, large or small.

Get in TouchGet in Touch

We use cookies to personalize content, improve site performance, and analyze traffic. Some cookies are essential for the site to function correctly. You can manage your preferences or accept all cookies.