When selecting metals for demanding industrial applications, weight matters as much as performance. Engineers often find themselves choosing between Hastelloy and stainless steel, two popular corrosion resistant metals with distinct characteristics.

Welcome to Moksh Tubes & Fittings LLP

Monday - Friday : 8:00 AM to 7:00 PM

-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Why Hastelloy Weighs More Than Stainless Steel

Why Hastelloy Weighs More Than Stainless Steel

While both materials offer excellent durability, Hastelloy consistently weighs more than stainless steel a difference that impacts everything from installation costs to structural requirements. This weight difference isn't coincidental; it stems from fundamental differences in their chemical composition and density.

In this guide, we'll explore exactly why Hastelloy is heavier, compare key specifications, and help you understand when this weight difference matters for your projects.

Understanding Hastelloy: The Heavy Duty Champion

What Makes Hastelloy Special?

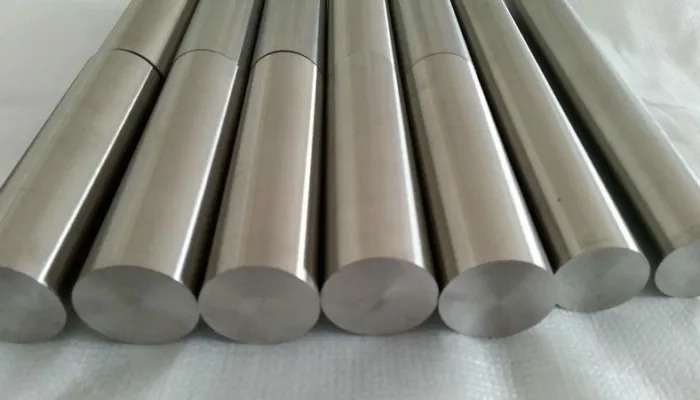

Hastelloy represents a family of nickel based superalloys engineered for extreme environments. These corrosion resistant metals excel where ordinary materials fail, particularly in chemical processing and marine applications.

- Nickel (Ni): 50-70% of the total composition

- Molybdenum (Mo): 10-16% for enhanced corrosion resistance

- Chromium (Cr): 15-22% for oxidation protection

- Iron (Fe): Minimal amounts, much lower than stainless steel

- Cobalt (Co): Up to 5% in certain grades

Common Hastelloy Applications

- Chemical processing equipment exposed to acids and alkalis

- Heat exchangers in power generation facilities

- Marine components requiring seawater resistance

- Pharmaceutical manufacturing equipment

- Aerospace components facing extreme temperatures

Stainless Steel: The Versatile Alternative

Composition and Characteristics

- 304 Stainless Steel 18% chromium, 8% nickel

- 316 Stainless Steel 16% chromium, 10% nickel, 2% molybdenum

- 310 Stainless Steel 25% chromium, 20% nickel (high-temperature grade)

Unlike nickel alloys such as Hastelloy, stainless steel relies primarily on iron as its base metal, contributing to its lighter weight profile.

Why Stainless Steel Remains Popular

- Cost effective for general applications

- Readily available in multiple grades

- Easier to machine and fabricate

- Sufficient corrosion resistance for most environments

- Lighter weight reduces structural requirements

The Science Behind Weight Differences

Density: The Primary Factor

- High Nickel Content: Nickel density 8.9 g/cm³ vs Iron 7.85 g/cm³, with 50–70% composition in Hastelloy.

- Molybdenum Addition: Very dense at 10.28 g/cm³, adds substantial weight but essential for chemical resistance.

- Cobalt Presence: Density 8.9 g/cm³, contributes to both weight and high temperature strength.

| Material | Density Range (g/cm³) | Primary Base Metal |

|---|---|---|

| Stainless Steel 304 | 7.9-8.0 | Iron (Fe) |

| Stainless Steel 316 | 8.0-8.1 | Iron (Fe) |

| Hastelloy C-276 | 8.9 | Nickel (Ni) |

| Hastelloy C-22 | 8.7 | Nickel (Ni) |

| Hastelloy B-2 | 9.2 | Nickel (Ni) |

Real World Impact of Weight Differences

- Support Requirements: Heavier components need reinforced mounting, stronger foundations, and lifting equipment.

- Transportation Costs: Higher shipping expenses, robust handling equipment, increased installation complexity.

- Cost Implications: Higher freight, labor, and installation costs but long term durability offsets expenses.

Making the Right Material Choice

When to Choose Welded Stainless Steel Pipes

Choose Hastelloy When: Extreme corrosion resistance, high temperatures, chemical compatibility, and long term durability are required.

Choose Stainless Steel When: Moderate corrosion resistance, lighter weight, budget sensitivity, and easier fabrication are priorities.

Future Trends in Metal Selection

- Titanium based superalloys

- Advanced aluminum lithium compositions

- Hybrid metal matrix composites

Engineers also increasingly use computer modeling, hollow section designs, and strategic material placement to minimize weight without sacrificing performance.

Conclusion

The weight difference between Hastelloy and stainless steel reflects their fundamental compositional differences. Hastelloy's higher density driven by substantial nickel and molybdenum content—delivers unmatched corrosion resistance in exchange for additional weight.

When selecting between these industrial metals, consider your specific requirements. If your application demands extreme chemical resistance or high-temperature performance, Hastelloy's weight premium pays dividends in reliability and longevity. For general applications, stainless steel's lighter weight and lower cost often provide the optimal balance.

Ready to specify the right material for your project? Consider consulting with materials engineers who can evaluate your specific requirements and recommend the optimal balance between performance, weight, and cost for your application.

FAQ's

How much heavier is Hastelloy compared to stainless steel?

Hastelloy typically weighs 10-15% more than stainless steel, with densities ranging from 8.7-9.2 g/cm³ versus 7.9-8.1 g/cm³ for stainless steel.

Does the extra weight affect Hastelloy's performance?

No, the higher density doesn't compromise performance. In fact, the elements that add weight also enhance corrosion resistance and high-temperature strength.

Can I substitute stainless steel for Hastelloy to save weight?

Only if your application doesn't require Hastelloy's superior corrosion resistance. In harsh chemical environments, this substitution could lead to premature failure.

Are there lightweight Hastelloy alternatives?

For specific applications, titanium alloys or specialized stainless steel grades might offer similar corrosion resistance with reduced weight, though typically at higher costs.

Recent Blogs

-

Hastelloy C276 vs Inconel 625 | Best Alloy for Chemical Plants

February 03, 2026

Locate Us

info@mokstubes.com

Office Address: Hinglaj Bhavan, Gulalwadi Mumbai, Maharashtra. 400004

Office Address: 6/A, Ground Floor, Rajwanti Mansion, Khetwadi Mumbai

Office Address: 95/95A, Dawood Baug, Sukhlaji Street, Kamatipura Mumbai

Office Address: 92E, Plot No. 3, New Tank Bunder, Darukhana, Mumbai, Maharashtra- 400 010.

get in touch

Let’s forge a connection — contact our team today.

Contact Us

At Moksh Tubes & Fittings LLP, we’re dedicated to making your purchases seamless — offering expert advice, a wide inventory of certified products, and global support for every order, large or small.

Get in TouchGet in Touch

We use cookies to personalize content, improve site performance, and analyze traffic. Some cookies are essential for the site to function correctly. You can manage your preferences or accept all cookies.