-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

Introduction to 14-4PH Stainless Steel | UNS S17400

14-4PH Stainless Steel is a martensitic precipitation-hardening stainless steel that offers an exceptional combination of high strength, corrosion resistance, and toughness. It contains 14% Chromium and 4% Nickel, along with controlled additions of copper and molybdenum, which enhance hardenability and resistance to stress corrosion cracking.

MOKSH TUBES & FITTINGS LLP offers a wide range of 14-4PH Stainless Steel products including pipes, sheets, bars, rods, and fittings designed for superior performance in aerospace, nuclear, marine, and petrochemical industries.

This alloy delivers excellent mechanical strength and corrosion resistance even under the most demanding service conditions, making it ideal for components requiring long-term durability and reliability.

Download High Strength Stainless Steel 14-4ph Datasheet

Get the complete High Strength Stainless Steel 14-4ph datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Material Summary – 17-4 PH Stainless Steel (UNS S17400)

| Property | Details |

|---|---|

| Material Type | Precipitation Hardening Martensitic Stainless Steel |

| Common Name | 17-4 PH (Also called 14-4 PH) |

| UNS Designation | S17400 |

| ASTM / AMS | ASTM A564 / AMS 5643 |

| Strengthening Mechanism | Copper Precipitation Hardening |

| Heat Treatable | ✔ Yes |

| Typical Hardness Range | 28 – 47 HRC |

| Corrosion Resistance | Comparable to SS 304 |

| Stress Corrosion Resistance | Excellent |

| Magnetic Property | Fully Magnetic |

| Typical Density | ~7.75 g/cm³ |

Chemical Composition of 17-4 PH Stainless Steel

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.07 max |

| Chromium (Cr) | 13.5 – 15.0 |

| Nickel (Ni) | 3.5 – 5.5 |

| Molybdenum (Mo) | 0.2 – 1.0 |

| Copper (Cu) | 1.5 – 2.5 |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 1.0 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

| Iron (Fe) | Balance |

Technical Composition of 17-4 PH Stainless Steel

Physical Properties of 17-4 PH Stainless Steel

| Property | Value |

|---|---|

| Density | 7.75 g/cm³ |

| Melting Range | 1400 – 1450°C |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | 18 W/m·K |

| Specific Heat | 500 J/kg·K |

Heat Treatment & Aging Conditions – 17-4 PH

| Condition | Aging Temp | Characteristics |

|---|---|---|

| Condition A | 1040°C + Air Cool | Soft, machinable |

| H900 | 482°C | Maximum strength & hardness |

| H1025 | 552°C | Balanced strength & toughness |

| H1075 | 580°C | Improved ductility |

| H1150 | 620°C | Best toughness & SCC resistance |

| H1150M | Double aged | Marine & nuclear service |

📌 Lower aging temperature → higher strength

📌 Higher aging temperature → higher toughness & corrosion resistance

Mechanical Properties of 17-4 PH Stainless Steel

| Property | Condition H900 | Condition H1150 |

|---|---|---|

| Tensile Strength (MPa) | 1310 | 930 |

| Yield Strength (0.2% MPa) | 1170 | 725 |

| Elongation (%) | 10 | 15 |

| Hardness (HRC) | 44 | 28 |

International Standards & Equivalent Grades – 17-4 PH

| Standard | Equivalent |

|---|---|

| UNS | S17400 |

| ASTM | A564, A693 |

| AMS | 5643, 5644 |

| EN | 1.4542 |

| DIN | X5CrNiCuNb16-4 |

| JIS | SUS 630 |

| ISO | X5CrNiCuNb16-4 |

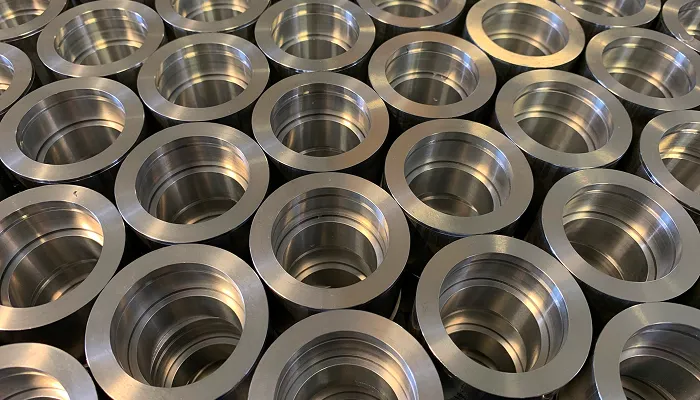

Products in 14-4PH Stainless Steel

MOKSH TUBES & FITTINGS LLP, with its extensive expertise in high-performance stainless steels and a strong global sourcing network, offers a comprehensive range of 14-4PH Stainless Steel (UNS S17400) products. Known for its exceptional mechanical strength, superior corrosion resistance, and outstanding toughness, 14-4PH is widely used in demanding industries such as Aerospace, Marine Engineering, Chemical Processing, Power Generation, Oil & Gas, and Defense.

This precipitation-hardening stainless steel grade is particularly well-suited for high-stress and high-temperature environments, where materials are required to retain structural integrity, shape, and performance under severe mechanical and thermal conditions. 14-4PH effectively meets these challenges, making it a preferred choice for critical components and applications where long-term durability, precision, and reliability are essential for operational success.

We offer 14-4PH Stainless Steel in a wide range of product forms.