-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

INTRODUCTION TO 17-4 PH STAINLESS STEEL / UNS S17400 / ASTM A564

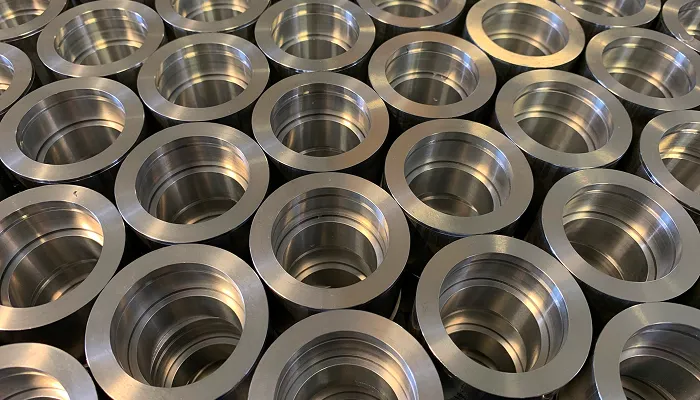

MOKSH TUBES & FITTINGS LLP is a leading supplier, exporter, importer, and stockist of a wide range of 17-4 PH Stainless Steel (UNS S17400) products including Pipes & Tubes, Pipe Fittings, Flanges, Fasteners, Sheets & Plates, Coils, Wires, Bars, Welding Rods, Mesh, and Custom Fabricated Components.

17-4 PH Stainless Steel is a precipitation-hardening martensitic stainless steel that combines high strength, excellent corrosion resistance, and ease of heat treatment into one versatile alloy. Its nominal composition includes chromium, nickel, and copper, which allow it to achieve very high tensile and yield strengths through a simple heat treatment process.

The alloy is magnetic in all conditions, weldable using conventional techniques, and can be machined efficiently in its solution-annealed or aged states. Due to its ability to develop high mechanical properties without extensive processing, 17-4 PH is widely used in aerospace, petrochemical, marine, power generation, and general engineering industries.

It performs well in mildly corrosive environments, similar to 304 stainless steel, and offers exceptional resistance to stress corrosion cracking in many applications. Its balance of strength, toughness, and corrosion resistance makes it one of the most commonly used precipitation-hardening stainless steels worldwide.

Download High Strength Stainless Steel 17-4ph Datasheet

Get the complete High Strength Stainless Steel 17-4ph datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Material Summary – 17-4 PH / Type 630 / UNS S17400

| Property | Details |

|---|---|

| Material Type | Precipitation Hardening Martensitic Stainless Steel |

| UNS Designation | S17400 |

| AISI / ASTM | Type 630 / ASTM A564 |

| Strengthening Method | Precipitation Hardening (Aging) |

| Heat Treatable | ✔ Yes (Solution + Aging) |

| Typical Hardness Range | 28 – 47 HRC (condition dependent) |

| Corrosion Resistance | Comparable to SS 304 |

| Stress Corrosion Resistance | Excellent |

| Magnetic Property | Fully Magnetic |

| Typical Density | ~7.75 g/cm³ |

📌 17-4 PH offers one of the best strength-to-corrosion-resistance ratios among stainless steels.

Chemical Composition of 17-4 PH Stainless Steel

| Element | Composition (%) |

|---|---|

| Chromium (Cr) | 15.00 – 17.50 |

| Nickel (Ni) | 3.00 – 5.00 |

| Copper (Cu) | 3.00 – 5.00 |

| Manganese (Mn) | 1.00 max |

| Silicon (Si) | 1.00 max |

| Columbium + Tantalum (Cb + Ta) | 0.15 – 0.45 |

| Carbon (C) | 0.07 max |

| Phosphorus (P) | 0.040 max |

| Sulfur (S) | 0.030 max |

| Iron (Fe) | Balance |

Technical Composition of 17-4 PH Stainless Steel

Physical Properties of 17-4 PH Stainless Steel

| Property | Value |

|---|---|

| Density | 7.75 g/cm³ |

| Melting Point | 1400–1440 °C |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | 18.4 W/m·K at 100 °C |

| Specific Heat | 500 J/kg·K |

| Electrical Resistivity | 0.80 µΩ·m |

Heat Treatment & Aging Conditions – 17-4 PH

| Condition | Aging Temp | Typical Properties |

|---|---|---|

| Condition A | 1040°C + Air Cool | Soft, machinable |

| H900 | 482°C | Maximum strength & hardness |

| H1025 | 552°C | Balanced strength & toughness |

| H1075 | 580°C | Improved toughness |

| H1150 | 620°C | Best toughness & SCC resistance |

| H1150M | Double aged | Marine & critical service |

📌 Lower aging temperature = higher strength

📌 Higher aging temperature = better toughness & corrosion resistance

Mechanical Properties of 17-4 PH (H900 Condition)

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 1310 MPa | 190,000 psi |

| Yield Strength (0.2%) | 1170 MPa | 170,000 psi |

| Elongation | 8–12 % | 8–12 % |

| Reduction of Area | 45 % | 45 % |

| Hardness | 40–47 HRC | 40–47 HRC |

| Impact Toughness | Good transverse & longitudinal toughness | |

Note: Properties depend on heat treatment conditions such as H900, H1025, H1150, etc.

International Standards & Equivalent Grades – 17-4 PH

| Standard | Equivalent |

|---|---|

| UNS | S17400 |

| ASTM | A564, A693 |

| AMS | 5643, 5644 |

| EN | 1.4542 |

| DIN | X5CrNiCuNb16-4 |

| JIS | SUS 630 |

| ISO | X5CrNiCuNb16-4 |

Products in 17-4 PH Stainless Steel

MOKSH TUBES & FITTINGS LLP, we supply a complete range of 17-4 PH Stainless Steel products tailored to meet diverse industrial applications. Backed by years of experience and a strong global sourcing network, we ensure top-quality materials that perform reliably under demanding and challenging service conditions.

We offer 17-4 PH Stainless Steel in various product forms to match your specific industrial requirements.