-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

Introduction to Stainless Steel 422 / UNS S42200 / AISI 422

MOKSH TUBES & FITTINGS LLP is a leading supplier, exporter, importer, and stockist of a complete range of Stainless Steel 422 (UNS S42200) products, including pipes & tubes, pipe fittings, flanges, fasteners, sheets & plates, coils, wires, round bars, flat bars, angles, channels, welding rods, wire mesh, and various custom or hard-to-find SS 422 products.

Stainless Steel 422 is a martensitic stainless steel alloy containing high chromium and moderate carbon, designed for excellent high-temperature strength, oxidation resistance, and good corrosion resistance in mild environments. It offers superior creep and stress rupture performance compared to conventional martensitic grades, making it ideal for turbine and high-heat service components.

SS 422 can be heat treated to achieve high mechanical strength and hardness, and it maintains good toughness even at elevated temperatures. With its combination of wear resistance, hardenability, and moderate corrosion resistance, SS 422 is an excellent choice for demanding industrial applications.

Download High Strength Stainless Steel 422 Datasheet

Get the complete High Strength Stainless Steel 422 datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Material Summary – SS 422 / UNS S42200

| Property | Details |

|---|---|

| Material Type | Martensitic Stainless Steel |

| UNS Designation | S42200 |

| AISI | 422 |

| EN Equivalent | X20CrMoV12-1 |

| Heat Treatable | ✔ Yes (Quench & Temper) |

| Strength Level | High (Elevated Temperature Capable) |

| Corrosion Resistance | Moderate (Better than SS 410 / 420) |

| Oxidation Resistance | Good up to ~600 °C |

| Magnetic Property | Magnetic |

| Typical Density | ~7.75 g/cm³ |

👉 SS 422 is designed for high-temperature service, maintaining strength and toughness after high-temperature tempering.

Chemical Composition of Stainless Steel 422

| Element | Composition (%) |

|---|---|

| Chromium (Cr) | 11.0 – 13.0 |

| Carbon (C) | 0.20 – 0.25 |

| Manganese (Mn) | 1.00 max |

| Silicon (Si) | 1.00 max |

| Nickel (Ni) | 0.50 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

| Molybdenum (Mo) | 0.50 max |

| Vanadium (V) | 0.20 – 0.50 |

| Iron (Fe) | Balance |

Technical Composition of Stainless Steel 422

Physical Properties of Stainless Steel 422

| Property | Value |

|---|---|

| Density | 7.75 g/cm³ |

| Melting Point | 1425 – 1510 °C |

| Modulus of Elasticity | 200 GPa |

| Magnetic Properties | Magnetic (Martensitic) |

| Condition | Heat treated and tempered |

Heat Treatment & Hardening Cycle – SS 422

| Process | Temperature Range | Purpose |

|---|---|---|

| Annealing | 840 – 900 °C | Improves machinability |

| Hardening (Austenitizing) | 1000 – 1050 °C | Prepares martensitic structure |

| Quenching | Oil / Air | Achieves high hardness |

| Tempering | 650 – 750 °C | Improves toughness & creep resistance |

| Stress Relieving | 600 – 650 °C | Reduces residual stresses |

📌 SS 422 is engineered to retain strength after high-temperature tempering, unlike conventional martensitic grades.

Mechanical Properties of Stainless Steel 422

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 655 – 965 MPa | 95,000 – 140,000 psi |

| Yield Strength (0.2%) | 450 – 655 MPa | 65,000 – 95,000 psi |

| Elongation | 15 – 20% | 15 – 20% |

| Hardness (Rockwell C) | 38 – 45 HRC | 38 – 45 HRC |

| Impact Toughness | Good | Good |

👉 Mechanical properties vary with specific heat treatment cycles and tempering temperatures.

International Standards & Equivalent Grades – SS 422

| Standard | Equivalent Grade |

|---|---|

| UNS | S42200 |

| AISI | 422 |

| EN | 1.4923 |

| DIN | X20CrMoV12-1 |

| ASTM | A276, A479 |

| JIS | SUS 422 |

| ISO | X20CrMoV12-1 |

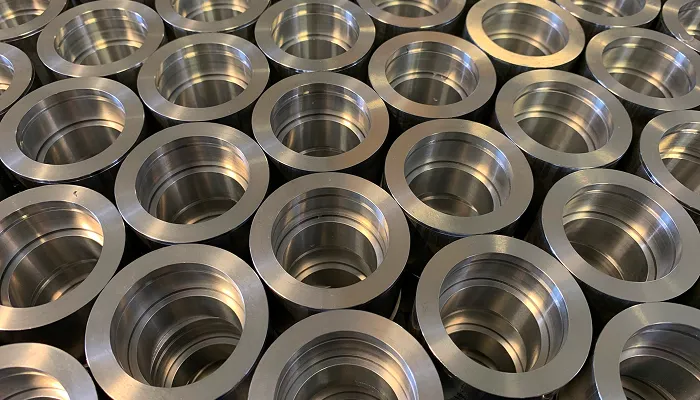

Products in Stainless Steel 422

MOKSH TUBES & FITTINGS LLP, with extensive experience in martensitic stainless steels and a strong global sourcing network, offers a comprehensive range of STAINLESS STEEL 422 products. These materials are engineered for high-stress, high-temperature, and wear-resistant applications, making them ideal for use in turbine components, aerospace parts, valves, petrochemical plants, and power generation equipment. Known for its excellent thermal stability, oxidation resistance, and mechanical strength, Stainless Steel 422 delivers exceptional performance and reliability in harsh industrial conditions.

We supply Stainless Steel 422 products manufactured in full compliance with ASTM A276, A479, A484, and other relevant international standards.