-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

Introduction To Inconel 600 / Alloy 600 / UNS N06600

MOKSH TUBES & FITTINGS LLP is a leading, supplier, exporter, importer, and stockist of high performance INCONEL 600 (UNS N06600) products. We offer a wide range of forms including Pipes & Tubes, Pipe Fittings, Flanges, Fasteners, Sheets & Plates, Coils, Wires, Round Bars, Flat Bars, Angles, Channels, Welding Rods, Wire Mesh, and other custom and hard to find Inconel 600 products.

INCONEL 600 is a nickel-chromium iron alloy designed for service temperatures from cryogenic to elevated levels in the range of 2000°F (1093°C). Known for its high strength and excellent oxidation and corrosion resistance, particularly in high temperature applications, INCONEL 600 also exhibits great mechanical properties and is readily weldable and formable. It is immune to chloride ion stress-corrosion cracking, non magnetic, and maintains stability under both oxidizing and reducing conditions. These properties make it ideal for a variety of industries including chemical processing, aerospace, marine, and heat treating equipment.

Download Inconel 600 Datasheet

Get the complete Inconel 600 datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Chemical Composition

| Element | Composition (%) | Nickel | 72.0 min (Balance) | Chromium | 14.0 – 17.0 | Iron | 6.0 – 10.0 | Carbon | 0.15 max | Manganese | 1.0 max | Sulfur | 0.015 max | Silicon | 0.5 max | Copper | 0.5 max |

|---|

Technical Composition

Physical Properties

| Property | Imperial | Metric | Density | 0.306 lb/in³ | 8.47 Mg/m³ | Melting Range | 2470–2575 °F | 1354–1413 °C | Specific Heat | 0.106 Btu/lb·°F | 444 J/kg·°C | Electrical Resistivity | 620 ohm·circ mil/ft | 1.03 µΩ·m | Curie Temperature | –192 °F | –124 °C | Permeability at 200 oersted (15.9 kA/m) | 1.010 | — |

|---|

Mechanical Properties

| Property | Rod & Bar (CD, Annealed) | Rod & Bar (CD, As-Drawn) | Rod & Bar (HF, Annealed) | Rod & Bar (HF) | Plate (Annealed) | Plate (As-Rolled) | Sheet (Annealed) | Sheet (Hard) | Strip (Annealed) | Strip (Spring Temper) | Tube/Pipe (HF) | Tube/Pipe (CD, Annealed) | Wire (Annealed) | Wire (No. 1 Temper) | Wire (Spring Temper) | Tensile Strength (ksi) | 80–100 | 105–150 | 80–100 | 85–120 | 80–105 | 85–110 | 80–100 | 120–150 | 80–100 | 145–170 | 75–100 | 80–100 | 80–120 | 105–135 | 170–220 | Tensile Strength (MPa) | 550–690 | 725–1035 | 550–690 | 585–830 | 550–725 | 580–760 | 550–690 | 830–1035 | 550–690 | 1000–1170 | 520–690 | 550–690 | 550–830 | 725–930 | 1170–1520 | Yield Strength (ksi) | 25–50 | 80–125 | 30–50 | 35–90 | 30–50 | 35–65 | 30–45 | 90–125 | 30–45 | 120–160 | 25–50 | 25–50 | 35–75 | 70–105 | 150–210 | Yield Strength (MPa) | 170–345 | 550–860 | 205–345 | 240–620 | 205–345 | 240–450 | 205–310 | 620–860 | 205–310 | 830–1100 | 170–345 | 170–345 | 240–520 | 480–725 | 1035–1450 | Elongation (%) | 55–35 | 30–10 | 55–35 | 50–30 | 55–35 | 50–30 | 55–35 | 15–2 | 55–35 | 10–2 | 55–35 | 55–35 | 45–20 | 35–15 | 5–2 | Hardness (Rockwell) | 65–85B | 90B–30C | 65–85B | 75–95B | 65–85B | 80–95B | 88B max | 24C min | 84B max | 30C min | – | 88B max | – | – | – |

|---|

Products in Inconel 600

INCONEL 600 designated as UNS N06600 and Werkstoff Nr. 2.4816, is a versatile nickel-chromium alloy known for its excellent resistance to oxidation and corrosion at high temperatures. Widely used in heat and corrosion-resistant applications, this alloy is officially approved under multiple sections of the ASME Boiler and Pressure Vessel Code, including:

This alloy meets several recognized industry standards, including:

Uses and Advantages

High resistance to oxidation and corrosion at elevated temperatures

High resistance to oxidation and corrosion at elevated temperatures

Resistance to chloride-ion stress-corrosion cracking

Good weldability and machinability

Outstanding performance in both oxidizing and reducing environments

Applications of Inconel 600

Inconel 600is a solid solution nickel-chromium-iron alloy known for its excellent resistance to heat and corrosion across a wide range of temperatures and environments. Its ability to retain strength and structural integrity under both oxidizing and reducing conditions makes it a highly versatile choice for multiple critical industries.

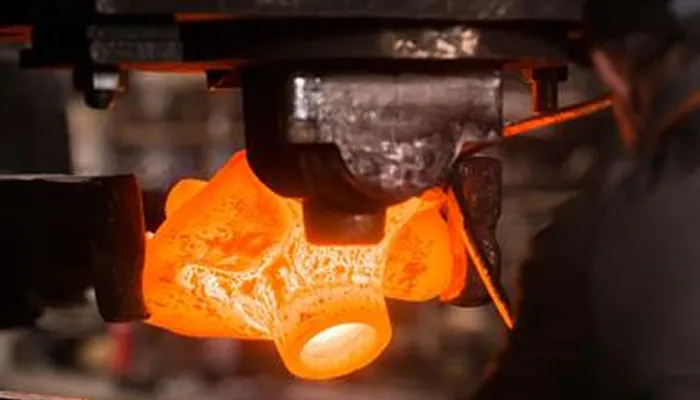

Heat Treatment and Industrial Furnaces

Commonly used for retorts, furnace fixtures, trays, muffles, and radiant tubes exposed to high temperatures. INCONEL 600 maintains mechanical strength and resists scaling in extreme thermal cycles.

Chemical Processing

Ideal for vessels, piping, and heat exchangers handling acidic, caustic, and chlorinated media. The alloy's resistance to chlorine, hydrogen chloride, and oxidizing salts ensures long-term stability and performance

Nuclear and Power Generation

Used in reactor core components, steam generator tubing, and fuel element spacers. INCONEL 600 offers good resistance to corrosion under high-purity water and steam conditions in nuclear power plants.

Food Processing and Pharmaceutical Equipment

Well-suited for systems exposed to organic and inorganic acids. Its non-magnetic properties and resistance to high-purity water make it reliable for hygienic applications.

Aerospace and Jet Engines

Used in components exposed to thermal and corrosive environments, such as engine parts, afterburner assemblies, and exhaust liners. INCONEL 600 offers excellent oxidation and creep resistance.

Marine and Offshore Systems

Provides excellent resistance to chloride-induced corrosion in saltwater environments. Often used in marine heat exchangers, pumps, and risers.

Cryogenic Applications

INCONEL 600 retains toughness and ductility at sub-zero temperatures, making it suitable for use in cryogenic storage and transfer systems.

WHY CHOOSE US?

FAQ's

What is Inconel 600 and why is it widely used?

Inconel 600 is a high performance nickel chromium iron alloy designed to withstand extreme temperatures and harsh environments. Known for its excellent oxidation and corrosion resistance, it remains stable under both oxidizing and reducing conditions. Because of its outstanding mechanical strength and resistance to chloride ion stress corrosion cracking, Inconel 600 is widely used in industries such as chemical processing, aerospace, marine engineering, and power generation.

What are the key properties of Inconel 600?

Inconel 600 is highly resistant to heat, scaling, and oxidation, even at temperatures up to 2000°F (1093°C). It offers superior strength, good weldability, and excellent resistance to chloride-ion stress-corrosion cracking. This alloy is non-magnetic, retains toughness at cryogenic temperatures, and performs well in both oxidizing and reducing environments, making it suitable for critical applications where durability and reliability are essential.

What are the common applications of Inconel 600?

Inconel 600 is used across multiple industries where high strength and corrosion resistance are required. It is commonly applied in heat treatment furnaces, nuclear power plants, and chemical processing equipment. Other applications include jet engine components, exhaust systems, marine heat exchangers, food processing equipment, and cryogenic storage systems. Its versatility and ability to withstand extreme environments make it a preferred choice for demanding projects.

How does Inconel 600 perform in chemical processing environments?

Inconel 600 is highly valued in chemical processing because of its resistance to acidic, caustic, and chloride-rich environments. It withstands exposure to chlorine, hydrogen chloride, and oxidizing salts without losing mechanical integrity. This makes it ideal for use in vessels, piping, and heat exchangers where long-term resistance to corrosion is critical, ensuring safe and reliable operation in aggressive chemical conditions.

Why choose MOKSH TUBES & FITTINGS LLP for Inconel 600 products?

MOKSH TUBES & FITTINGS LLP is a trusted global supplier of premium Inconel 600 products in various forms including pipes, tubes, fittings, flanges, fasteners, sheets, plates, and custom-fabricated components. With strong sourcing from certified mills, advanced manufacturing expertise, and strict quality assurance, the company ensures superior product performance. Clients benefit from timely delivery, custom fabrication support, and a commitment to customer satisfaction, making MOKSH a reliable partner for Inconel 600 solutions worldwide.

blogs

Inconel 625 vs Inconel 718: De...

Inconel alloys are some of the...

How Inconel Performs Under Ext...

When it comes to materials tha...

Welding Guidelines for Inconel...

Inconel is one of the world’s...Contact Us

For inquiries or to request a quote, reach out to Moksh Tubes & Fittings LLP your reliable source for INCONEL 600 products engineered for performance, precision, and reliability.

Get in Touch