-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

Introduction To Inconel 617 / Alloy 617 / UNS N06617

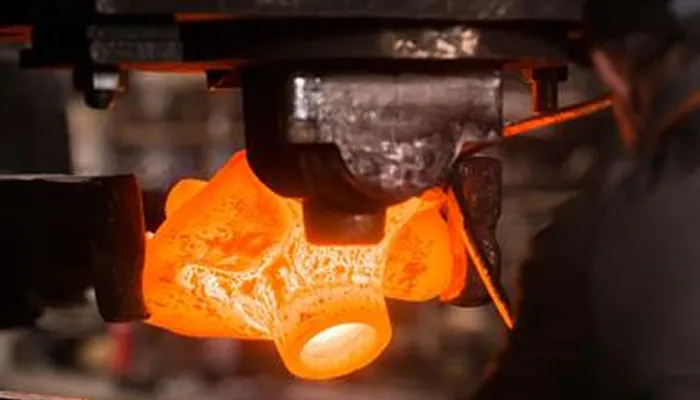

MOKSH TUBES & FITTINGS LLP is a trusted supplier, exporter, importer, and stockist of premium-grade Inconel 617 products including pipes, tubes, sheets, plates, coils, bars, pipe fittings, flanges, fasteners, welding rods, wire mesh, and custom-fabricated components.

INCONEL 617 is a nickel chromium cobalt molybdenum alloy engineered for excellent high temperature strength and outstanding resistance to oxidation and carburization. It offers superior metallurgical stability and resistance to a wide range of corrosive environments, making it ideal for service in extreme conditions such as combustion and flue gas environments. The alloy retains its mechanical properties at elevated temperatures, providing long-term service life in heat-exposed applications. It also offers excellent weldability and workability across varied manufacturing conditions.

Download Inconel 617 Datasheet

Get the complete Inconel 617 datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Duplex Stainless Steel S31803 Specifications

| Category | Details |

|---|---|

| Grade | INCONEL 617 / Alloy 617 / UNS N06617 |

| Material Type | Nickel-Chromium-Cobalt-Molybdenum High-Temperature Alloy |

| Forms Available | Pipes, Tubes, Sheets, Plates, Coils, Bars, Fittings, Flanges, Fasteners |

| Standards | ASTM B166, B168, B546, B564, ASME SB166 / SB168 / SB564 / SB546 |

| Certification | EN 10204 3.1 / 3.2 |

| ASME Approval | ASME Code Cases 1956, 1982 |

| Applications | High-temperature, oxidizing & carburizing environments |

Chemical Composition of INCONEL 617

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 44.5 min |

| Chromium (Cr) | 20.0 – 24.0 |

| Cobalt (Co) | 10.0 – 15.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Aluminum (Al) | 0.8 – 1.5 |

| Titanium (Ti) | 0.6 max |

| Carbon (C) | 0.05 – 0.15 |

| Iron (Fe) | 3.0 max |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 1.0 max |

| Sulfur (S) | 0.015 max |

| Copper (Cu) | 0.5 max |

| Boron (B) | 0.006 max |

Technical Composition (Physical & Thermal Properties)

Physical Properties of INCONEL 617

| Property | Imperial | Metric |

|---|---|---|

| Density | 0.302 lb/in³ | 8.36 g/cm³ |

| Melting Range | 2430–2510 °F | 1332–1380 °C |

| Specific Heat | 0.100 Btu/lb·°F | 419 J/kg·°C |

| Electrical Resistivity | 736 ohm·cir·mil/ft | 1.22 µΩ·m |

Heat Treatment of INCONEL 617

| Process | Description |

|---|---|

| Solution Annealing | 2150–2200°F (1175–1205°C), rapid quench |

| Stress Relieving | 1650–1800°F (900–980°C) |

| Aging | Not typically age-hardened — strengthening occurs via solid-solution & carbide precipitation |

Mechanical Properties of INCONEL 617

| Form | Yield Strength | Tensile Strength | Elongation | Hardness |

|---|---|---|---|---|

| Plate (Hot Rolled) | 46.7 ksi / 322 MPa | 106.5 ksi / 734 MPa | 62% | 172 BHN |

| Bar (Hot Rolled) | 46.1 ksi / 318 MPa | 111.5 ksi / 769 MPa | 56% | 181 BHN |

| Tubing (Cold Drawn) | 55.6 ksi / 383 MPa | 110.0 ksi / 758 MPa | 56% | 193 BHN |

| Sheet / Strip (Cold Rolled) | 50.9 ksi / 351 MPa | 109.5 ksi / 755 MPa | 58% | 173 BHN |

International Standards & Equivalent Grades

| Standard | Equivalent Grade |

|---|---|

| UNS | N06617 |

| W.Nr. | 2.4663a |

| ISO | 6208 |

| ASTM | B166 / B168 / B546 / B564 |

| ASME | SB166 / SB168 / SB564 / SB546 |

Products in Inconel 617

INCONEL 617 identified as UNS N06617 and Werkstoff Nr. 2.4663a, is a high-performance nickel-chromium-cobalt-molybdenum alloy known for its exceptional strength and oxidation resistance at high temperatures. It is approved for pressure vessel construction under ASME Code Cases 1956 and 1982, making it an excellent choice for demanding industrial applications.

This alloy meets several recognized industry standards, including:

Uses and Advantages

Exceptional high-temperature strength and metallurgical stability

Superior resistance to oxidation, nitriding, and carburization

Good resistance to a broad spectrum of corrosive environments

Excellent weldability and formability for ease of fabricationGood weldability and machinability

Maintains structural integrity in temperatures up to 1100°C

Applications of Inconel 617

Inconel 617 is a high-performance nickel-chromium-cobalt-molybdenum alloy designed for superior strength and corrosion resistance in extreme temperature environments. Its exceptional ability to withstand oxidation, carburization, and thermal cycling makes it a trusted choice in industries where components are pushed to their limits.

Aerospace and Gas Turbines

Used in combustion liners, transition ducts, and other critical hot-section parts in jet engines and gas turbines. INCONEL 617 delivers high creep strength, oxidation resistance, and structural integrity at temperatures above 1000°C (1832°F).

Power Generation (Fossil & Nuclear)

Ideal for recuperators, heat exchangers, and steam generator tubing in advanced fossil fuel and nuclear power systems. The alloy retains strength and resists degradation in high-pressure, high-temperature conditions, including supercritical CO₂ and helium-cooled reactors.

Petrochemical and Refining Plants

Relied upon in reformers, flare tips, catalyst grids, and furnace internals where high heat and aggressive chemical exposure are present. Its resistance to oxidizing and reducing atmospheres helps prolong equipment life.

Industrial Furnace Equipment

Commonly used in radiant tubes, heat shields, retorts, trays, and other components exposed to constant heating and cooling. INCONEL 617 resists scaling and structural weakening during repeated thermal cycles.

Waste Incineration and Pollution Control

Applied in components such as liners, baffles, and exhaust ducts exposed to corrosive gases at elevated temperatures, helping improve safety and durability in emission-heavy environments.

Chemical Processing

Ideal for equipment that must handle aggressive chemical mixtures at elevated temperatures. Its metallurgical stability and corrosion resistance provide reliability for the long haul.

Heat Recovery Systems

Used in recuperators and high-efficiency heat exchangers, especially in systems where thermal performance, oxidation resistance, and material longevity are crucial.

WHY CHOOSE US?

Inconel 617 Price per kg in India

Typical Range: ₹3,500 – ₹7,500 per kg

(Price varies by size, thickness, form & quantity.)

Contact us for exact quotation based on size and quantity.

FAQ's

What is Inconel 617 and what makes it unique?

Inconel 617 is a high performance nickel chromium cobalt molybdenum alloy designed for exceptional strength, oxidation resistance, and carburization resistance at elevated temperatures. Its unique chemical composition provides excellent metallurgical stability, making it ideal for demanding industrial environments such as aerospace, power generation, and petrochemical processing. Unlike conventional alloys, Inconel 617 retains its mechanical properties even in extreme heat and corrosive conditions, ensuring long-term durability and reliability.

What are the main applications of Inconel 617?

Inconel 617 is widely used in industries where components must withstand high temperatures and aggressive environments. Common applications include jet engine hot-section parts, gas turbines, heat exchangers, recuperators, steam generator tubing, chemical processing equipment, reformers, and furnace internals. The alloy’s superior creep strength and resistance to oxidation, nitriding, and carburization make it especially suitable for aerospace, nuclear power plants, petrochemical facilities, waste incineration, and heat recovery systems.

What are the advantages of using Inconel 617 over other alloys?

The biggest advantage of Inconel 617 is its ability to maintain mechanical strength and structural integrity at temperatures up to 1100°C while resisting oxidation and carburization. It also offers excellent weldability, machinability, and formability, making fabrication easier across diverse industries. Compared to conventional alloys, Inconel 617 provides longer service life in severe environments, reduces maintenance costs, and ensures reliable performance in both oxidizing and reducing atmospheres.

How does the chemical composition of Inconel 617 enhance its properties?

The chemical composition of Inconel 617, which includes nickel, chromium, cobalt, and molybdenum, plays a vital role in its superior performance. Nickel provides overall strength and corrosion resistance, chromium improves oxidation resistance, cobalt enhances stability at high temperatures, and molybdenum contributes to creep resistance and toughness. The balance of these elements ensures outstanding resistance to thermal cycling, aggressive chemicals, and environmental degradation, making it one of the most versatile high temperature alloys available.

Why choose Moksh Tubes & Fittings LLP for Inconel 617 products?

Moksh Tubes & Fittings LLP is a trusted manufacturer, supplier, exporter, importer, and stockist of premium Inconel 617 products, offering a complete range including pipes, tubes, sheets, plates, flanges, fittings, fasteners, and custom fabricated components. With strong sourcing networks, advanced manufacturing capabilities, and strict quality control, the company ensures that every product meets international standards and industry specific requirements. Backed by global logistics support and technical expertise, Moksh Tubes & Fittings LLP provides reliable Inconel 617 solutions for critical industrial applications.

blogs

Inconel 625 vs Inconel 718: De...

Inconel alloys are some of the...

How Inconel Performs Under Ext...

When it comes to materials tha...

Welding Guidelines for Inconel...

Inconel is one of the world’s...Contact Us

Moksh Tubes & Fittings LLP your trusted partner for INCONEL 617 solutions built for durability, strength, and superior performance in the most demanding environments.

Get in Touch