-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

Introduction To Inconel 625 / Alloy 625 / UNS N06625

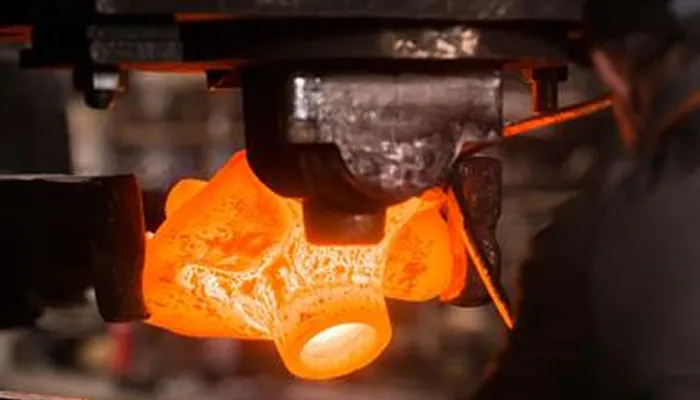

MOKSH TUBES & FITTINGS LLP is a manufacturer, supplier, exporter, importer and stockist of a wide range of INCONEL 625 (UNS N06625) products including Pipes & Tubes, Pipe Fittings, Flanges, Fasteners, Sheets & Plates, Coils, Wires, Round Bars, Flat Bars, Angles, Channels, Welding Rods, Wire Mesh, and other Custom and Hard-to-Find INCONEL 625 Products.

MOKSH TUBES & FITTINGS LLP is a trusted supplier, stockist, importer, and exporter of INCONEL 625 products in a wide range of forms, sizes, and specifications.

INCONEL 625 is a nickel chromium molybdenum niobium alloy known for its outstanding corrosion resistance, high strength, and excellent fatigue and thermal fatigue properties. The alloy exhibits exceptional resistance to a wide range of corrosive environments, including oxidizing and reducing acids, chlorides, seawater, and harsh chemical media. Its high nickel content provides superior resistance to chloride-induced stress corrosion cracking, while the addition of molybdenum and niobium enhances its mechanical strength and resistance to pitting and crevice corrosion.

Download Inconel 625 Datasheet

Get the complete Inconel 625 datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Duplex Stainless Steel S31803 Specifications

| Category | Details |

|---|---|

| Grade | INCONEL® 625 |

| UNS | N06625 |

| Alloy Type | Nickel-Chromium-Molybdenum-Niobium Alloy |

| Condition Supplied | Annealed / Solution Treated / Cold Worked |

| Heat Treatment | Solution Annealed (No precipitation hardening) |

| Magnetic Nature | Non-Magnetic |

| Weldability | Excellent |

| Testing | Chemical, Mechanical, PMI, UT / ET |

| Certification | EN 10204 3.1 / 3.2 |

Chemical Composition of INCONEL 625

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 58 min (Balance) |

| Chromium (Cr) | 20 – 23 |

| Molybdenum (Mo) | 8 – 10 |

| Niobium + Tantalum (Nb + Ta) | 3.15 – 4.15 |

| Iron (Fe) | ≤ 5 |

| Cobalt (Co) | ≤ 1.0 |

| Manganese (Mn) | ≤ 0.50 |

| Silicon (Si) | ≤ 0.50 |

| Aluminum (Al) | ≤ 0.40 |

| Titanium (Ti) | ≤ 0.40 |

| Carbon (C) | ≤ 0.10 |

| Phosphorus (P) | ≤ 0.015 |

| Sulfur (S) | ≤ 0.015 |

Technical Specifications of Alloy 625

Physical Properties of Alloy 625

| Property | Imperial | Metric |

|---|---|---|

| Density | 0.305 lb/in³ | 8.44 g/cm³ |

| Melting Range | 2350–2460°F | 1290–1350°C |

| Curie Temperature | -320°F | -196°C |

| Permeability (200 Oe) | 1.0006 | 1.0006 |

Heat Treatment of INCONEL 625

| Process | Temperature Range | Purpose |

|---|---|---|

| Solution Annealing | 1090 – 1200°C | Restores ductility & corrosion resistance |

| Cooling | Rapid water quench | Prevents carbide precipitation |

| Stress Relieving | 600 – 650°C | Dimensional stability (if required) |

INCONEL 625 does not require precipitation hardening; strength is achieved through alloy chemistry.

Mechanical Properties of INCONEL 625

| Condition | Tensile Strength (ksi / MPa) | Yield Strength (ksi / MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| Rod / Bar / Plate (As-Rolled) | 120–160 ksi / 827–1103 MPa | 60–110 ksi / 414–758 MPa | 30–60% | 175–240 |

| Rod / Bar / Plate (Annealed) | 120–150 ksi / 827–1034 MPa | 60–95 ksi / 414–655 MPa | 30–60% | 145–220 |

| Rod / Bar / Plate (Solution Treated) | 105–130 ksi / 724–896 MPa | 42–60 ksi / 290–414 MPa | 40–65% | 116–194 |

| Sheet / Strip (Annealed) | 120–150 ksi / 827–1034 MPa | 60–90 ksi / 414–621 MPa | 30–55% | — |

| Tube / Pipe (Cold Drawn & Annealed) | 120–140 ksi / 827–965 MPa | 60–75 ksi / 414–517 MPa | 30–55% | — |

| Tube / Pipe (Cold Drawn & Solution Treated) | 100–120 ksi / 689–827 MPa | 40–60 ksi / 276–414 MPa | 40–60% | — |

International Standards & Equivalent Grades

| Standard | Equivalent |

|---|---|

| UNS | N06625 |

| W.Nr | 2.4856 |

| DIN | NiCr22Mo9Nb |

| ISO | NiCr22Mo9Nb |

| ASTM | Alloy 625 |

Products in Inconel 625

INCONEL 625 is a versatile and highly reliable material widely used across many industries. It complies with important industry standards like NACE MR-01-75 and is available in a broad range of shapes and sizes to fit your needs.

This alloy meets several recognized industry standards, including:

Uses and Advantages

Resists a broad spectrum of corrosive environments

Maintains strength and integrity at elevated temperatures

Exceptional fatigue resistance and thermal stability

Easy to fabricate and weld

Superior defense against pitting, crevice corrosion, and stress corrosion cracking

Applications of Inconel 625

Inconel 625 is a highly versatile nickel-chromium-molybdenum-niobium alloy known for its exceptional corrosion resistance, high strength, and durability in extreme environments. Its ability to withstand aggressive chemicals, high pressures, and wide temperature ranges makes it a preferred material across a variety of critical industries.

Aerospace Industry

Widely used in jet engine components, exhaust systems, ducting, and turbine shroud rings. INCONEL 625 offers excellent fatigue strength and thermal stability under high mechanical and thermal stress.

Marine and Offshore Applications

Highly resistant to seawater, pitting, crevice corrosion, and chloride-induced stress corrosion cracking. Common applications include seawater piping, underwater components, marine fasteners, and offshore platform structures.

Chemical Processing

Performs reliably in environments involving strong acids such as nitric, phosphoric, and sulfuric acids. Ideal for heat exchangers, reactors, scrubbers, and transfer piping handling corrosive fluids at elevated temperatures.

Power Generation and Nuclear Reactors

Used in superheaters, steam lines, containment vessels, and heat exchanger tubing. INCONEL 625 resists oxidation and maintains mechanical properties under high heat and pressure, including radiation environments.

Oil & Gas Sector

Ideal for sour gas service, wellhead components, flexible joints, manifolds, and downhole equipment. Its resistance to hydrogen sulfide and chlorides ensures long-lasting performance in offshore and deep well operations.

Environmental and Pollution Control Systems

Suitable for flue gas scrubbers, incinerator linings, and waste processing systems that involve acidic or high-temperature gas streams.

Pharmaceutical and Food Processing

Used in high-purity process piping, steam sterilizers, and acid-resistant components where hygiene and corrosion resistance are essential.

WHY CHOOSE US?

INCONEL 625 Price per kg in India

Typical Range: ₹4,200 – ₹7,500 per kg

(Size, form, condition & certification)

Contact us for exact quotation based on size and quantity.

FAQ's

What is Inconel 625 and why is it widely used?

Inconel 625 (UNS N06625) is a nickel chromium molybdenum niobium alloy known for its exceptional corrosion resistance, high strength, and remarkable fatigue and thermal fatigue properties. It performs reliably in extreme environments, including exposure to seawater, strong acids, and high pressure, high temperature conditions. The alloy’s unique chemical balance gives it superior resistance to pitting, crevice corrosion, and chloride induced stress corrosion cracking, making it a preferred material across industries such as aerospace, marine, chemical processing, oil and gas, and power generation.

What are the primary applications of Inconel 625?

Inconel 625 is used in a wide variety of industries where durability and corrosion resistance are critical. In aerospace, it is applied in jet engine components, exhaust systems, and turbine shroud rings. In the marine and offshore sector, it is relied upon for seawater piping, underwater fasteners, and platform structures. The alloy also sees extensive use in chemical plants for reactors, scrubbers, and heat exchangers; in power generation for steam lines and containment vessels; and in oil and gas industries for sour gas service, downhole equipment, and manifolds. Its versatility extends to environmental systems, pharmaceuticals, and food processing industries.

What are the main advantages of Inconel 625 compared to other alloys?

Inconel 625 offers a unique combination of high tensile strength, excellent fatigue resistance, and outstanding corrosion resistance in both oxidizing and reducing environments. Unlike many alloys, it retains its mechanical properties even under extreme thermal cycling, making it ideal for demanding service conditions. Its resistance to aggressive chemicals, seawater, hydrogen sulfide, and chloride rich environments sets it apart as a reliable, long lasting material. Additionally, it is easy to fabricate, weld, and machine, which helps industries reduce downtime and maintenance costs.

How does the chemical composition of Inconel 625 enhance its properties?

The chemical composition of Inconel 625 is carefully balanced to deliver superior performance. A high nickel content provides resistance to chloride stress corrosion cracking, while chromium improves resistance to oxidation and scaling. The addition of molybdenum enhances its defense against pitting and crevice corrosion, and niobium increases strength and toughness through solid solution strengthening. These elements together give Inconel 625 unmatched durability in seawater, acidic media, and high-temperature environments, making it a truly versatile alloy for critical applications.

Why choose Moksh Tubes & Fittings LLP for Inconel 625 products?

Moksh Tubes & Fittings LLP is a trusted manufacturer, supplier, exporter, importer, and stockist of premium Inconel 625 products, offering everything from pipes, tubes, sheets, plates, and coils to fittings, flanges, fasteners, and custom-fabricated components. With proven expertise in nickel-based alloys, a strong global supply network, and stringent quality control standards, the company ensures that every product meets international specifications. Customers rely on Moksh Tubes & Fittings LLP for customized solutions, timely delivery, and consistent performance across industries where reliability is non negotiable.

blogs

Inconel 625 vs Inconel 718: De...

Inconel alloys are some of the...

How Inconel Performs Under Ext...

When it comes to materials tha...

Welding Guidelines for Inconel...

Inconel is one of the world’s...Contact Us

Moksh Tubes & Fittings LLP for inquiries or quotes – your trusted partner for world-class INCONEL 625 products.

Get in Touch