-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

Introduction To Inconel 718 / Alloy 718 / UNS N07718

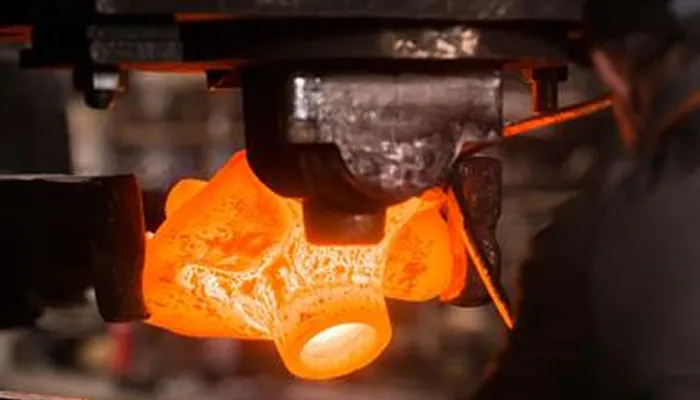

MOKSH TUBES & FITTINGS LLP proudly manufactures, supplies, exports, and stocks a wide range of INCONEL 718 (UNS N07718) products. These include Pipes & Tubes, Pipe Fittings, Flanges, Fasteners, Sheets & Plates, Coils, Wires, Round Bars, Flat Bars, Angles, Channels, Welding Rods, Wire Mesh, and other custom and difficult-to-source Alloy 718 components.

INCONEL 718 is a nickel chromium alloy known for its excellent high strength, corrosion resistance, and weldability, particularly in high temperature environments ranging from cryogenic up to 700°C (1290°F). A key advantage of INCONEL 718 is its ability to be precipitation hardened, providing high tensile, fatigue, creep, and rupture strength. It is highly resistant to post-weld cracking, oxidation, and a wide range of corrosive environments. These properties make it ideal for use in the aerospace, marine, chemical processing, and power generation industries.

Download Inconel 718 Datasheet

Get the complete Inconel 718 datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

INCONEL 718 Specifications

| Category | Details |

|---|---|

| Grade | INCONEL® 718 |

| UNS | N07718 |

| Alloy Family | Nickel-Based Superalloy |

| Condition Supplied | Solution Annealed, Aged, Cold Worked |

| Heat Treatment | Solution Annealed + Aged |

| Welding | Excellent (No post-weld cracking) |

| Testing | Chemical, Mechanical, PMI, UT / RT (on request) |

| Certification | EN 10204 3.1 / 3.2 |

Chemical Composition of INCONEL 718

| Element | Range (%) |

|---|---|

| Nickel (Ni + Co) | 50.0 – 55.0 |

| Chromium (Cr) | 17.0 – 21.0 |

| Iron (Fe) | Balance |

| Niobium (Nb + Ta) | 4.75 – 5.50 |

| Molybdenum (Mo) | 2.80 – 3.30 |

| Titanium (Ti) | 0.65 – 1.15 |

| Aluminum (Al) | 0.20 – 0.80 |

| Cobalt (Co) | ≤ 1.00 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 0.35 |

| Silicon (Si) | ≤ 0.35 |

| Phosphorus (P) | ≤ 0.015 |

| Sulfur (S) | ≤ 0.015 |

| Boron (B) | ≤ 0.006 |

| Copper (Cu) | ≤ 0.30 |

Technical Composition of Alloy 718

Physical Properties of Alloy 718

| Property | Condition | Value |

|---|---|---|

| Density | Annealed | 0.296 lb/in³ |

| Density | Annealed & Aged | 0.297 lb/in³ |

| Melting Range | — | 2300–2437°F (1260–1336°C) |

| Specific Heat | — | 0.104 Btu/lb°F (435 J/kg°C) |

| Curie Temperature | Annealed | -320°F (< –196°C) |

| Curie Temperature | Aged | -170°F (–112°C) |

| Magnetic Permeability @ 200 Oersted | Annealed | 1.0013 |

| Magnetic Permeability @ 200 Oersted | Aged | 1.0011 |

Heat Treatment of INCONEL 718

| Process | Temperature Range | Purpose |

|---|---|---|

| Solution Annealing | 940 – 980°C | Dissolves precipitates, restores ductility |

| Aging (Single) | 720°C → 620°C | Develops high strength |

| Double Aging | 720°C + 620°C | Improves creep & fatigue resistance |

| Stress Relieving | 600 – 650°C | Dimensional stability |

INCONEL 718 achieves strength only through precipitation hardening.

Mechanical Properties of Inconel 718

| Condition | Tensile Strength | Yield Strength | Elongation | Hardness | Impact Strength |

|---|---|---|---|---|---|

| Cold Worked + Solution Annealed + Aged | High | High | 40–30% | High | ≥ 20 ft-lb |

| Hot Worked + Solution Annealed + Aged | High | High | 40–30% | High | ≥ 20 ft-lb |

| Heavy Section (203–254 mm) | Slightly Lower | Slightly Lower | 25% | High | ≥ 20 ft-lb |

INCONEL 718 provides exceptional creep rupture strength, fatigue life, and fracture toughness.

International Standards & Equivalent Grades

| Standard | Equivalent |

|---|---|

| UNS | N07718 |

| W.Nr | 2.4668 |

| DIN | NiCr19NbMo |

| AMS | 5662 / 5663 / 5664 |

| ISO | NiCr19NbMo |

Products in Inconel 718

INCONEL 718 products suitable for high-stress, high-temperature, and cryogenic applications. These products are widely used in aerospace, power generation, oil & gas, chemical processing, and marine engineering.

This alloy meets several recognized industry standards, including:

Uses and Advantages

Outstanding strength and durability across a wide temperature range

Precipitation hardenable for enhanced mechanical performance

Excellent weldability without post-weld cracking

High resistance to stress corrosion cracking, pitting, and crevice corrosion

Exceptional fatigue and creep-rupture strength

Applications of Inconel 600

Inconel 718 is a precipitation-hardenable nickel-chromium alloy known for its outstanding strength, corrosion resistance, and creep-rupture performance at temperatures up to 700°C (1290°F). Its unique ability to combine weldability, high yield strength, and resistance to oxidation makes it a trusted material for mission-critical components across multiple industries.

Aerospace and Jet Engines

Used extensively in turbine discs, compressor blades, engine casings, fasteners, and exhaust parts. INCONEL 718 maintains strength and fatigue resistance under extreme conditions, making it ideal for flight-critical components.

Gas Turbines and Power Generation

Applied in land-based turbines, transition ducts, combustion liners, and hardware that must endure prolonged exposure to high heat and pressure.

Nuclear and Marine Applications

Selected for components like core support structures, reactor pressure boundaries, springs, and fasteners that require high strength and stability in corrosive or radioactive environments.

Automotive and Motorsports

Employed in turbocharger rotors, exhaust valves, and high-performance engine components where resistance to heat and mechanical stress is critical.

Oil and Gas Exploration

Commonly used in downhole tools, wellhead equipment, fasteners, and mandrels. INCONEL 718 performs exceptionally well in high-pressure, high-temperature (HPHT) wells and corrosive environments containing hydrogen sulfide and chlorides.

Cryogenic Storage and Transportation

Thanks to its excellent toughness and ductility at low temperatures, it’s often used in cryogenic vessels, valves, and structural parts for liquefied gas systems.

Chemical Processing Equipmen

Used in heat exchangers, reactor vessels, and processing units where both strength and corrosion resistance are needed in acidic and oxidizing chemical environments

WHY CHOOSE US?

INCONEL 718 Price per kg in India

Typical Range: ₹4,800 – ₹8,500 per kg

(Price depends on form, size, heat treatment & certification)

Contact us for exact quotation based on size and quantity.

FAQ's

What is Inconel 718 and what makes it special?

Inconel 718 (UNS N07718) is a high-performance nickel-chromium alloy known for its outstanding strength, corrosion resistance, and weldability in extreme temperature environments. Unlike many other alloys, Inconel 718 can be precipitation hardened, which gives it superior tensile, fatigue, creep, and rupture strength. It performs reliably from cryogenic temperatures up to 700°C (1290°F) while resisting oxidation, post weld cracking, and corrosive attack, making it a preferred material for aerospace, marine, chemical processing, and power generation industries.

Where is Inconel 718 commonly used?

Inconel 718 is widely applied across industries that demand both mechanical strength and corrosion resistance. In aerospace, it is used for turbine discs, compressor blades, casings, and fasteners. Power generation plants rely on it for gas turbines, transition ducts, and combustion hardware. It also plays a key role in nuclear and marine components, automotive and motorsport engine parts, oil and gas exploration tools, cryogenic storage systems, and chemical processing equipment where long term stability in aggressive environments is crucial.

What are the key advantages of Inconel 718?

The main advantages of Inconel 718 include its outstanding strength across a wide temperature range, excellent weldability without post-weld cracking, and its ability to be precipitation hardened for enhanced mechanical performance. It offers superior resistance to stress corrosion cracking, pitting, and crevice corrosion while maintaining exceptional fatigue and creep-rupture strength. These properties make it highly durable and cost effective for industries where materials must withstand high pressure, extreme heat, and chemically aggressive conditions.

How does the chemical composition of Inconel 718 enhance its performance?

The chemical composition of Inconel 718 includes 50–55% nickel, 17–21% chromium, and controlled additions of niobium, molybdenum, titanium, and aluminum, with iron making up the balance. The nickel chromium base provides superior corrosion resistance in oxidizing and reducing environments, while niobium and molybdenum contribute to precipitation hardening for improved strength. Titanium and aluminum enhance creep resistance and structural stability, giving Inconel 718 the ability to maintain its mechanical properties under extreme operating conditions.

Why choose Moksh Tubes & Fittings LLP for Inconel 718 products?

Moksh Tubes & Fittings LLP is a trusted global manufacturer, supplier, exporter, importer, and stockist of Inconel 718 products in various forms, including pipes, tubes, fittings, flanges, fasteners, sheets, plates, coils, wires, bars, and custom-fabricated components. With unmatched expertise in high performance nickel alloys, a wide inventory of rare materials, advanced engineering capabilities, and a strong international supply chain, the company ensures timely delivery and top-quality products. Customers prefer Moksh Tubes & Fittings LLP for its commitment to precision, reliability, and global compliance standards in every Inconel 718 solution.

blogs

Inconel 625 vs Inconel 718: De...

Inconel alloys are some of the...

How Inconel Performs Under Ext...

When it comes to materials tha...

Welding Guidelines for Inconel...

Inconel is one of the world’s...Contact Us

For quotes, custom orders, or technical support, reach out to Moksh Tubes & Fittings LLP your reliable supplier of INCONEL 718 products built for precision, strength, and performance in demanding applications.

Get in Touch